THÔNG TIN CƠ BẢN

KHP109 Copper Alloy Coil is a specialized copper alloy developed for applications requiring high electrical conductivity and good mechanical strength. It is a popular choice in the electronics and electrical industries.

Key characteristics of KHP109 Copper Alloy Coil:

- Chemical Composition:

- The KHP109 alloy typically contains copper (Cu) as the main component, along with other alloying elements to enhance the material's mechanical and electrical properties.

- Physical Properties:

- Electrical and Thermal Conductivity: KHP109 has excellent electrical and thermal conductivity, nearly equivalent to pure copper.

- Strength and Hardness: This alloy has high tensile strength and hardness, allowing it to withstand applications involving significant mechanical stress.

- Ductility: KHP109 is highly ductile, making it easy to bend and fabricate without breaking or cracking.

- Applications:

- Electronics Industry: Used in electrical contacts, wiring, and electronic components due to its high electrical conductivity.

- Electrical Industry: Employed as a material for busbars, heat-resistant wires, and other components requiring strength and good electrical conductivity.

- Precision Mechanics: Applied in the production of mechanical components that require high precision and stability.

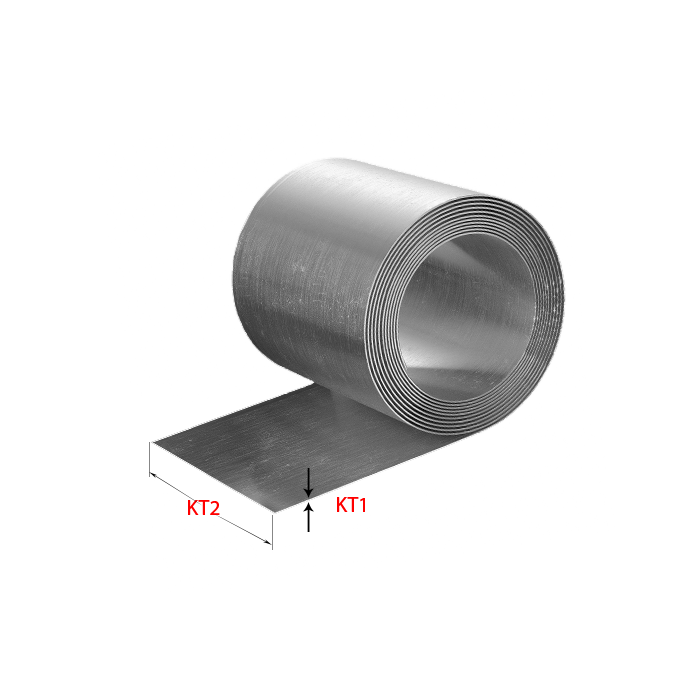

- Shape and Size:

- KHP109 is typically available in coil form, which can be cut and shaped according to specific application requirements.

Manufacturing and Processing:

- KHP109 copper alloy coil is produced through modern casting and rolling processes, ensuring high precision in dimensions and mechanical properties of the final product.

(Source: Internet)

Key characteristics of KHP109 Copper Alloy Coil:

- Chemical Composition:

- The KHP109 alloy typically contains copper (Cu) as the main component, along with other alloying elements to enhance the material's mechanical and electrical properties.

- Physical Properties:

- Electrical and Thermal Conductivity: KHP109 has excellent electrical and thermal conductivity, nearly equivalent to pure copper.

- Strength and Hardness: This alloy has high tensile strength and hardness, allowing it to withstand applications involving significant mechanical stress.

- Ductility: KHP109 is highly ductile, making it easy to bend and fabricate without breaking or cracking.

- Applications:

- Electronics Industry: Used in electrical contacts, wiring, and electronic components due to its high electrical conductivity.

- Electrical Industry: Employed as a material for busbars, heat-resistant wires, and other components requiring strength and good electrical conductivity.

- Precision Mechanics: Applied in the production of mechanical components that require high precision and stability.

- Shape and Size:

- KHP109 is typically available in coil form, which can be cut and shaped according to specific application requirements.

Manufacturing and Processing:

- KHP109 copper alloy coil is produced through modern casting and rolling processes, ensuring high precision in dimensions and mechanical properties of the final product.

(Source: Internet)