THÔNG TIN CƠ BẢN

ABB2 Copper Alloy is a type of copper alloy widely used in applications requiring high electrical conductivity, good mechanical strength, and corrosion resistance. This alloy is chosen for heavy industrial applications and harsh environments.

Key characteristics of ABB2 Copper Alloy:

- Chemical Composition:

- ABB2 contains a high copper (Cu) content, along with other metals like zinc (Zn) and sometimes tin (Sn) or nickel (Ni), enhancing its strength and corrosion resistance.

- Physical Properties:

- Good Electrical Conductivity: With high copper content, ABB2 offers excellent electrical and thermal conductivity, making it ideal for electrical and thermal applications.

- Strength and Hardness: This alloy provides high mechanical strength and suitable hardness for load-bearing applications.

- Corrosion Resistance: ABB2 has good corrosion resistance, especially in atmospheric environments and corrosive solutions.

- Applications:

- Electrical Industry: Widely used in electrical components, cables, and other conductive parts.

- Marine Industry: Used in marine applications due to its corrosion resistance in seawater environments.

- Mechanical Engineering: Applied in manufacturing mechanical parts like shafts, valves, and other load-bearing components.

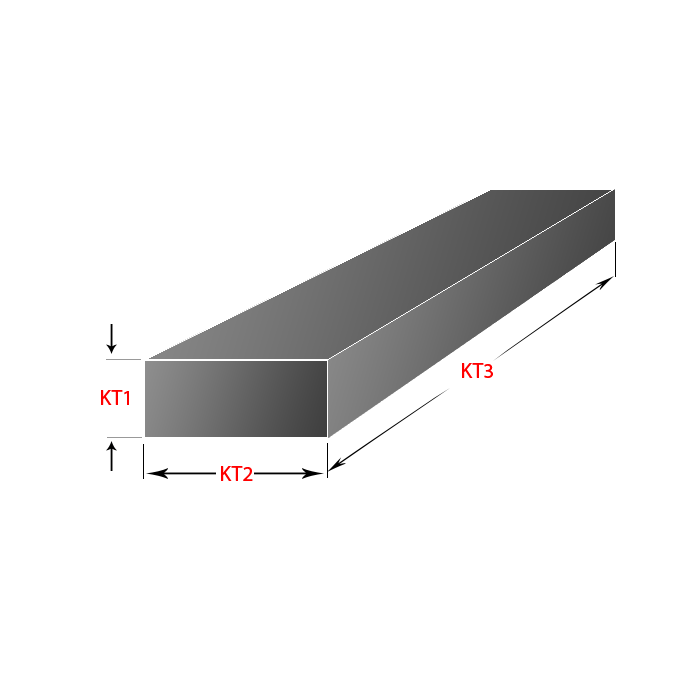

- Shape and Size:

- ABB2 copper alloy is typically available in forms such as rods, plates, tubes, and other custom shapes depending on specific requirements.

Manufacturing and Processing:

- ABB2 is produced through casting, rolling, and can be further processed using methods such as cutting, turning, and welding. The good machinability of this alloy helps optimize production costs.

(Source: Internet)

Key characteristics of ABB2 Copper Alloy:

- Chemical Composition:

- ABB2 contains a high copper (Cu) content, along with other metals like zinc (Zn) and sometimes tin (Sn) or nickel (Ni), enhancing its strength and corrosion resistance.

- Physical Properties:

- Good Electrical Conductivity: With high copper content, ABB2 offers excellent electrical and thermal conductivity, making it ideal for electrical and thermal applications.

- Strength and Hardness: This alloy provides high mechanical strength and suitable hardness for load-bearing applications.

- Corrosion Resistance: ABB2 has good corrosion resistance, especially in atmospheric environments and corrosive solutions.

- Applications:

- Electrical Industry: Widely used in electrical components, cables, and other conductive parts.

- Marine Industry: Used in marine applications due to its corrosion resistance in seawater environments.

- Mechanical Engineering: Applied in manufacturing mechanical parts like shafts, valves, and other load-bearing components.

- Shape and Size:

- ABB2 copper alloy is typically available in forms such as rods, plates, tubes, and other custom shapes depending on specific requirements.

Manufacturing and Processing:

- ABB2 is produced through casting, rolling, and can be further processed using methods such as cutting, turning, and welding. The good machinability of this alloy helps optimize production costs.

(Source: Internet)