THÔNG TIN CƠ BẢN

Aluminum Alloy ANP79 is a specially designed aluminum alloy for applications requiring a combination of high strength and good corrosion resistance. This alloy is commonly used in the aerospace industry and high-tech applications.

Key Characteristics of Aluminum Alloy ANP79:

- Chemical Composition:

- Aluminum Alloy ANP79 typically contains aluminum (Al) with key alloying elements such as copper (Cu), magnesium (Mg), and zinc (Zn). The specific composition may vary based on application requirements, but the primary goal is to optimize the balance between strength and corrosion resistance.

- Physical Properties:

- High Strength: ANP79 is designed to provide good mechanical strength, making it suitable for structural applications.

- Corrosion Resistance: This alloy offers good corrosion resistance, enhancing the longevity of the product in harsh environments.

- Machinability: ANP79 can be machined and heat-treated to achieve desired mechanical properties.

- Applications:

- Aerospace Industry: ANP79 is used in aircraft structural components due to its strength and corrosion resistance.

- Machinery Manufacturing: Applied in machinery parts requiring high strength and corrosion resistance.

- Construction: Used in building and engineering applications that demand load-bearing and corrosion-resistant materials.

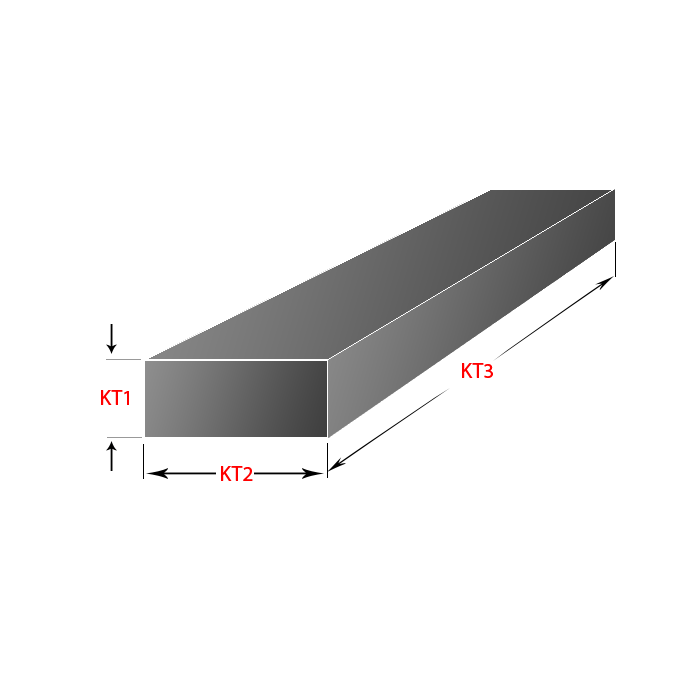

- Shape and Size:

- Aluminum Alloy ANP79 is typically available in forms such as sheets, bars, tubes, or custom-shaped products depending on specific application needs.

Manufacturing and Processing:

- Aluminum ANP79 is produced through hot and cold rolling processes and is often heat-treated to enhance its mechanical properties. To protect against corrosion, this alloy may be anodized or coated.

(Source: Internet)

Key Characteristics of Aluminum Alloy ANP79:

- Chemical Composition:

- Aluminum Alloy ANP79 typically contains aluminum (Al) with key alloying elements such as copper (Cu), magnesium (Mg), and zinc (Zn). The specific composition may vary based on application requirements, but the primary goal is to optimize the balance between strength and corrosion resistance.

- Physical Properties:

- High Strength: ANP79 is designed to provide good mechanical strength, making it suitable for structural applications.

- Corrosion Resistance: This alloy offers good corrosion resistance, enhancing the longevity of the product in harsh environments.

- Machinability: ANP79 can be machined and heat-treated to achieve desired mechanical properties.

- Applications:

- Aerospace Industry: ANP79 is used in aircraft structural components due to its strength and corrosion resistance.

- Machinery Manufacturing: Applied in machinery parts requiring high strength and corrosion resistance.

- Construction: Used in building and engineering applications that demand load-bearing and corrosion-resistant materials.

- Shape and Size:

- Aluminum Alloy ANP79 is typically available in forms such as sheets, bars, tubes, or custom-shaped products depending on specific application needs.

Manufacturing and Processing:

- Aluminum ANP79 is produced through hot and cold rolling processes and is often heat-treated to enhance its mechanical properties. To protect against corrosion, this alloy may be anodized or coated.

(Source: Internet)