THÔNG TIN CƠ BẢN

C2680 Copper Alloy is a type of copper alloy, belonging to the group of copper-zinc alloys (also known as brass), with copper and zinc as the main components. This alloy is widely used in various industries due to its mechanical properties and good workability.

Key characteristics of C2680 Copper Alloy:

- Chemical Composition:

- C2680 contains approximately 65% copper (Cu) and 35% zinc (Zn), creating an alloy that balances strength, ductility, and corrosion resistance.

- Physical Properties:

- Electrical and Thermal Conductivity: C2680 has good electrical and thermal conductivity, though lower than pure copper.

- Hardness and Strength: This alloy has higher hardness and strength compared to pure copper, while still maintaining good ductility, making it easy to work with.

- Color: C2680 typically has the characteristic yellow color of brass, is easy to polish, and has high aesthetic appeal.

- Chemical Properties:

- Corrosion Resistance: C2680 offers good corrosion resistance in many environments, especially in air and freshwater.

- Applications:

- Electronics and Electrical Industry: Used in connectors, electronic components, and parts requiring good electrical and thermal conductivity.

- Mechanical and Manufacturing: Commonly used in machinery parts and mechanical equipment due to its mechanical properties and good machinability.

- Construction and Decoration: Employed in decorative details, interior furnishings, and structural parts due to its color and durability.

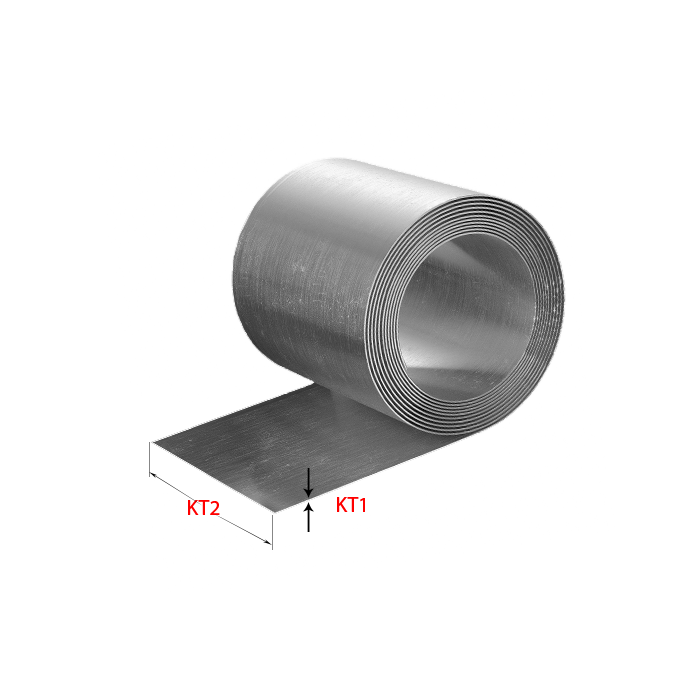

- Shape and Size:

- C2680 copper alloy is available in forms such as bars, sheets, coils, and custom-fabricated products according to specific requirements.

Manufacturing and Processing:

- C2680 copper alloy is produced through processes such as casting, rolling, and cold working. The production process is tightly controlled to ensure the quality and consistency of the final product.

(Source: Internet)

Key characteristics of C2680 Copper Alloy:

- Chemical Composition:

- C2680 contains approximately 65% copper (Cu) and 35% zinc (Zn), creating an alloy that balances strength, ductility, and corrosion resistance.

- Physical Properties:

- Electrical and Thermal Conductivity: C2680 has good electrical and thermal conductivity, though lower than pure copper.

- Hardness and Strength: This alloy has higher hardness and strength compared to pure copper, while still maintaining good ductility, making it easy to work with.

- Color: C2680 typically has the characteristic yellow color of brass, is easy to polish, and has high aesthetic appeal.

- Chemical Properties:

- Corrosion Resistance: C2680 offers good corrosion resistance in many environments, especially in air and freshwater.

- Applications:

- Electronics and Electrical Industry: Used in connectors, electronic components, and parts requiring good electrical and thermal conductivity.

- Mechanical and Manufacturing: Commonly used in machinery parts and mechanical equipment due to its mechanical properties and good machinability.

- Construction and Decoration: Employed in decorative details, interior furnishings, and structural parts due to its color and durability.

- Shape and Size:

- C2680 copper alloy is available in forms such as bars, sheets, coils, and custom-fabricated products according to specific requirements.

Manufacturing and Processing:

- C2680 copper alloy is produced through processes such as casting, rolling, and cold working. The production process is tightly controlled to ensure the quality and consistency of the final product.

(Source: Internet)