THÔNG TIN CƠ BẢN

C7521 Copper Alloy, also known as Nickel Silver or Nickel Brass, is a copper alloy with high nickel (Ni) and zinc (Zn) content. This alloy is known for its high hardness, good corrosion resistance, and moderate electrical conductivity, making it suitable for various applications requiring high aesthetic appeal along with good mechanical strength.

Key characteristics of C7521 Copper Alloy:

- Chemical Composition:

- C7521 contains approximately 65% copper (Cu), 18% nickel (Ni), and 17% zinc (Zn). This composition gives the alloy a beautiful, often silver-like appearance, along with good corrosion resistance and mechanical strength.

- Physical Properties:

- High Hardness and Strength: C7521 offers high hardness and strength, making it suitable for applications requiring durability and resilience.

- Corrosion Resistance: This alloy has good corrosion resistance, particularly in humid environments and when exposed to mild chemicals.

- Electrical and Thermal Conductivity: While not as conductive as pure copper, C7521 still provides sufficient electrical and thermal conductivity for specialized applications.

- Applications:

- Decorative and Jewelry Industry: Due to its shiny appearance and good corrosion resistance, C7521 is often used in the manufacture of jewelry and decorative items.

- Musical Instrument Manufacturing: Used in the production of musical instrument parts, such as brass instruments, thanks to its corrosion resistance and aesthetic appeal.

- Electronics Industry: Applied in electronic components and connectors that require good electrical and mechanical properties.

- Lock and Hardware Manufacturing: C7521 is widely used in the production of locks, door handles, and other metal fittings due to its high hardness and strength.

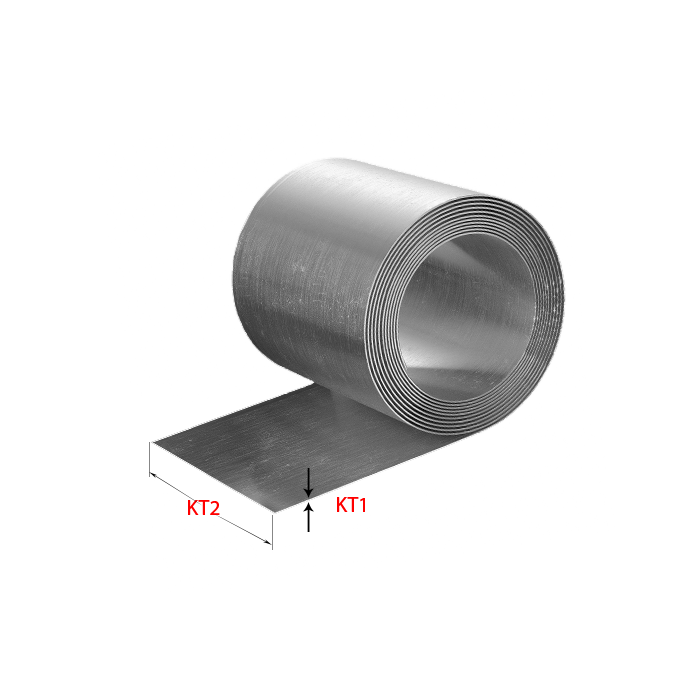

- Shape and Size:

- C7521 copper alloy is typically available in forms such as sheets, wires, bars, or tubes, catering to various industrial application requirements.

Manufacturing and Processing:

- C7521 is produced through casting, rolling, and heat treatment processes to achieve the desired mechanical properties. The alloy can then be further processed through methods such as cutting, stamping, and bending.

(Source: Internet)

Key characteristics of C7521 Copper Alloy:

- Chemical Composition:

- C7521 contains approximately 65% copper (Cu), 18% nickel (Ni), and 17% zinc (Zn). This composition gives the alloy a beautiful, often silver-like appearance, along with good corrosion resistance and mechanical strength.

- Physical Properties:

- High Hardness and Strength: C7521 offers high hardness and strength, making it suitable for applications requiring durability and resilience.

- Corrosion Resistance: This alloy has good corrosion resistance, particularly in humid environments and when exposed to mild chemicals.

- Electrical and Thermal Conductivity: While not as conductive as pure copper, C7521 still provides sufficient electrical and thermal conductivity for specialized applications.

- Applications:

- Decorative and Jewelry Industry: Due to its shiny appearance and good corrosion resistance, C7521 is often used in the manufacture of jewelry and decorative items.

- Musical Instrument Manufacturing: Used in the production of musical instrument parts, such as brass instruments, thanks to its corrosion resistance and aesthetic appeal.

- Electronics Industry: Applied in electronic components and connectors that require good electrical and mechanical properties.

- Lock and Hardware Manufacturing: C7521 is widely used in the production of locks, door handles, and other metal fittings due to its high hardness and strength.

- Shape and Size:

- C7521 copper alloy is typically available in forms such as sheets, wires, bars, or tubes, catering to various industrial application requirements.

Manufacturing and Processing:

- C7521 is produced through casting, rolling, and heat treatment processes to achieve the desired mechanical properties. The alloy can then be further processed through methods such as cutting, stamping, and bending.

(Source: Internet)