THÔNG TIN CƠ BẢN

14Z Copper Alloy is a type of copper alloy containing small amounts of other metals such as zinc (Zn) and sometimes nickel (Ni), which provide mechanical and physical properties suitable for a variety of industrial applications. This alloy is often valued for its ductility, strength, and good corrosion resistance.

Key characteristics of 14Z Copper Alloy:

- Chemical Composition:

- 14Z mainly consists of copper (Cu) with small amounts of zinc (Zn) and sometimes nickel (Ni). This composition balances strength and machinability.

- Physical Properties:

- Ductility and Machinability: 14Z is highly ductile, allowing it to be easily machined into various shapes without breaking or deforming.

- Good Strength and Hardness: This alloy offers good strength and hardness, making it suitable for various engineering applications.

- Corrosion Resistance: With a high copper content, 14Z offers good corrosion resistance, especially in atmospheric and water environments.

- Applications:

- Mechanical Engineering: Widely used in manufacturing mechanical parts such as shafts, valves, and gears due to its good mechanical properties.

- Electronics Industry: Used in electronic components and connectors due to its good electrical conductivity.

- Construction Industry: Applied in decorative items and furniture fittings.

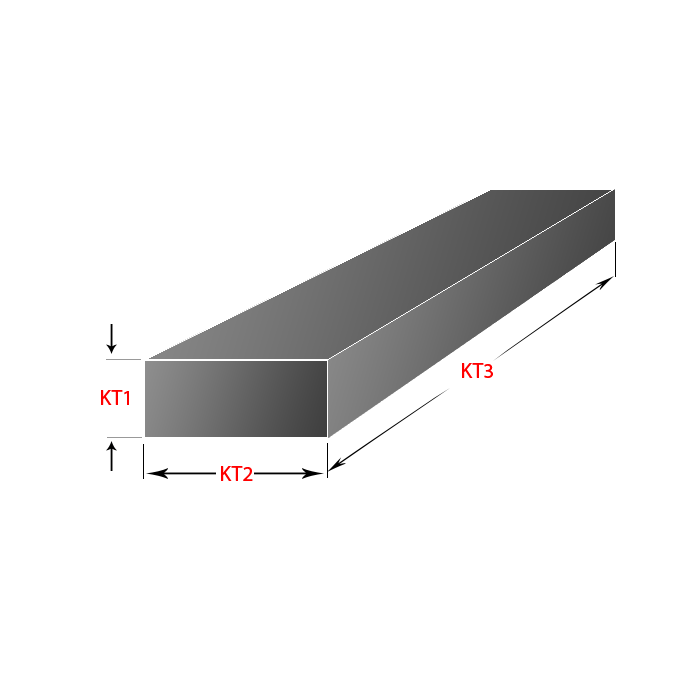

- Shape and Size:

- 14Z copper alloy is typically available in forms such as rods, tubes, wires, and sheets, catering to various application needs.

Manufacturing and Processing:

- 14Z is produced through casting and rolling processes, followed by further machining using methods such as cutting, turning, and stamping. The good machinability of this alloy helps optimize costs and increase production efficiency.

(Source: Internet)

Key characteristics of 14Z Copper Alloy:

- Chemical Composition:

- 14Z mainly consists of copper (Cu) with small amounts of zinc (Zn) and sometimes nickel (Ni). This composition balances strength and machinability.

- Physical Properties:

- Ductility and Machinability: 14Z is highly ductile, allowing it to be easily machined into various shapes without breaking or deforming.

- Good Strength and Hardness: This alloy offers good strength and hardness, making it suitable for various engineering applications.

- Corrosion Resistance: With a high copper content, 14Z offers good corrosion resistance, especially in atmospheric and water environments.

- Applications:

- Mechanical Engineering: Widely used in manufacturing mechanical parts such as shafts, valves, and gears due to its good mechanical properties.

- Electronics Industry: Used in electronic components and connectors due to its good electrical conductivity.

- Construction Industry: Applied in decorative items and furniture fittings.

- Shape and Size:

- 14Z copper alloy is typically available in forms such as rods, tubes, wires, and sheets, catering to various application needs.

Manufacturing and Processing:

- 14Z is produced through casting and rolling processes, followed by further machining using methods such as cutting, turning, and stamping. The good machinability of this alloy helps optimize costs and increase production efficiency.

(Source: Internet)