THÔNG TIN CƠ BẢN

CAC403C Copper Alloy is a type of copper alloy commonly used in applications that require corrosion resistance, good mechanical strength, and easy machinability. This alloy typically includes copper (Cu), zinc (Zn), and tin (Sn), creating a type of brass with excellent properties for industrial and marine applications.

Key characteristics of CAC403C Copper Alloy:

- Chemical Composition:

- CAC403C primarily consists of copper (Cu) with a certain proportion of zinc (Zn) to enhance strength and tin (Sn) to improve corrosion resistance.

- Physical Properties:

- Corrosion Resistance: CAC403C offers good corrosion resistance, particularly in marine environments and high-humidity conditions.

- Strength and Hardness: This alloy provides good strength and hardness, making it suitable for applications requiring load-bearing and wear resistance.

- Ease of Machining: CAC403C is easy to machine using methods such as cutting, turning, and welding, with a good surface finish after processing.

- Applications:

- Marine Industry: Used in ship components, valves, and equipment exposed to seawater due to its excellent corrosion resistance.

- Mechanical Engineering: Employed in the production of machinery parts and components requiring high durability and wear resistance.

- Construction Industry: Used in structural details and architectural fittings due to its aesthetic appeal and durability.

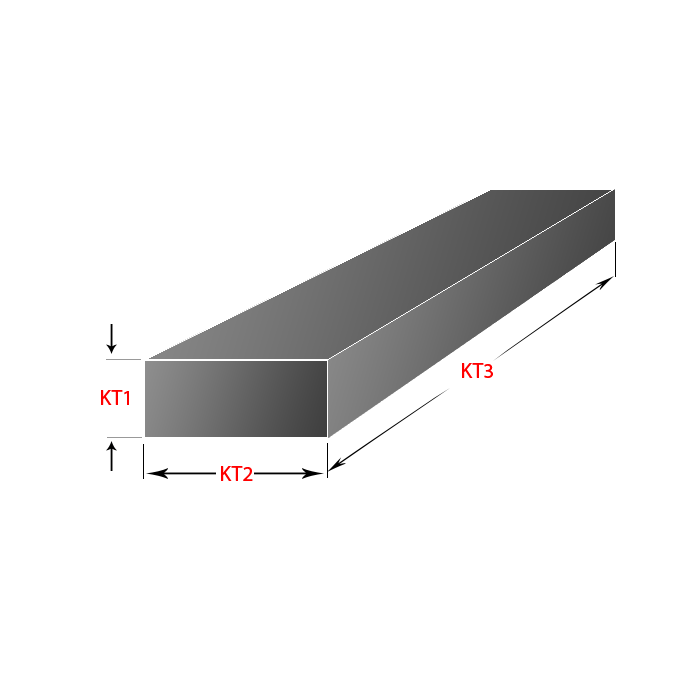

- Shape and Size:

- CAC403C copper alloy is typically available in forms such as rods, plates, tubes, and other product forms depending on application requirements.

Manufacturing and Processing:

- CAC403C is produced through casting and rolling processes and can be machined using standard mechanical methods. The alloy also has good weldability, making it easy to form complex structures.

(Source: Internet)