THÔNG TIN CƠ BẢN

Refined Copper C1800 is a copper-beryllium alloy known for its superior mechanical properties, including high strength, hardness, and good wear resistance. Also known as beryllium copper, this alloy is commonly used in applications requiring both hardness and good electrical conductivity.

Key Characteristics of Refined Copper C1800:

- Chemical Composition:

- Refined Copper C1800 contains a small amount of beryllium (around 1.6-2.0%), combined with other elements like cobalt or nickel, which enhances the alloy’s strength and hardness.

- Physical Properties:

- High Strength and Hardness: Due to the beryllium content, C1800 exhibits high tensile strength and excellent hardness, making it ideal for mechanical applications.

- Good Wear and Corrosion Resistance: This alloy offers good resistance to wear and corrosion, ensuring durability in harsh working environments.

- Good Electrical and Thermal Conductivity: While not as conductive as pure copper, C1800 still provides sufficient electrical and thermal conductivity for use in many industrial applications.

- Applications:

- Electronics and Electrical Power: Used in electrical contacts, switches, connectors, and components requiring high conductivity and strength.

- Mold Making Technology: Employed in the production of molds, particularly in plastic and metal processing, due to its hardness and strength.

- Aerospace and Defense Industry: Utilized in aircraft components and military equipment requiring high strength and wear resistance.

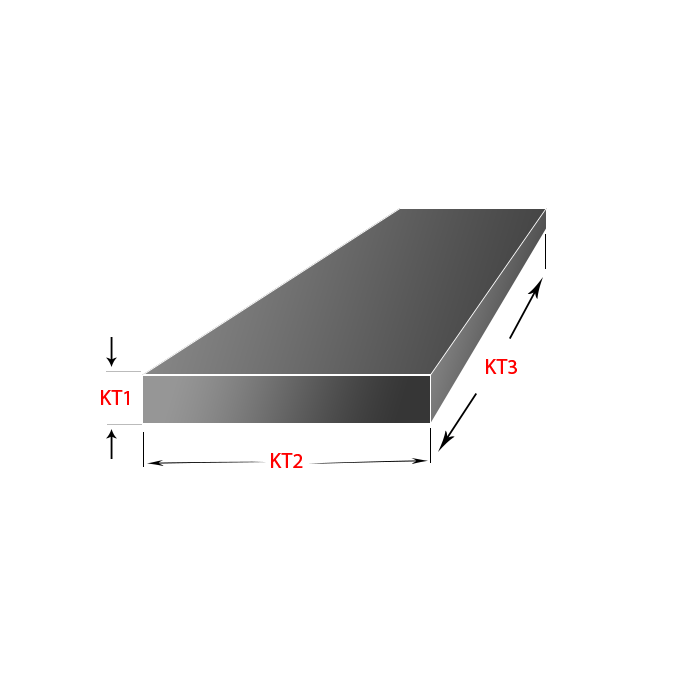

- Shape and Size:

- Refined Copper C1800 is typically available in the form of rods, sheets, wires, or other product forms depending on specific application requirements.

Manufacturing and Processing:

- Copper C1800 is produced through an alloying process in which beryllium and other elements are added to pure copper. After production, this alloy can be processed to achieve desired shapes and sizes, ensuring optimal mechanical properties.

(Source: Internet)

Key Characteristics of Refined Copper C1800:

- Chemical Composition:

- Refined Copper C1800 contains a small amount of beryllium (around 1.6-2.0%), combined with other elements like cobalt or nickel, which enhances the alloy’s strength and hardness.

- Physical Properties:

- High Strength and Hardness: Due to the beryllium content, C1800 exhibits high tensile strength and excellent hardness, making it ideal for mechanical applications.

- Good Wear and Corrosion Resistance: This alloy offers good resistance to wear and corrosion, ensuring durability in harsh working environments.

- Good Electrical and Thermal Conductivity: While not as conductive as pure copper, C1800 still provides sufficient electrical and thermal conductivity for use in many industrial applications.

- Applications:

- Electronics and Electrical Power: Used in electrical contacts, switches, connectors, and components requiring high conductivity and strength.

- Mold Making Technology: Employed in the production of molds, particularly in plastic and metal processing, due to its hardness and strength.

- Aerospace and Defense Industry: Utilized in aircraft components and military equipment requiring high strength and wear resistance.

- Shape and Size:

- Refined Copper C1800 is typically available in the form of rods, sheets, wires, or other product forms depending on specific application requirements.

Manufacturing and Processing:

- Copper C1800 is produced through an alloying process in which beryllium and other elements are added to pure copper. After production, this alloy can be processed to achieve desired shapes and sizes, ensuring optimal mechanical properties.

(Source: Internet)