THÔNG TIN CƠ BẢN

SUS 301 CSP Stainless Steel is an austenitic stainless steel known for its good corrosion resistance, high strength, and excellent formability. SUS 301 CSP is commonly used in applications requiring high tensile strength and ductility, such as in the automotive, aerospace, and electronics industries.

Key Characteristics of SUS 301 CSP Stainless Steel:

- Chemical Composition:

- Carbon (C): Maximum 0.15%, enhances tensile strength and hardness.

- Chromium (Cr): 16.0-18.0%, provides corrosion and oxidation resistance.

- Nickel (Ni): 6.0-8.0%, improves mechanical properties and corrosion resistance.

- Manganese (Mn): Maximum 2.0%, enhances the steel's machinability.

- Silicon (Si): Maximum 1.0%, contributes to strength and hardness.

- Physical Properties:

- Tensile Strength: SUS 301 CSP has high tensile strength, ranging from approximately 930-1100 MPa, depending on the processing state.

- Ductility: Offers good formability for bending, cutting, and shaping, thanks to its ductile nature.

- Corrosion Resistance: While not as corrosion-resistant as SUS 304, SUS 301 CSP still offers resistance to corrosion in mild and moderate environments.

- Hardness: Can achieve higher hardness through cold working, making it suitable for applications requiring high hardness and strength.

- Applications:

- Automotive Industry: Used in components requiring high strength and elasticity, such as springs, structural parts, and fasteners.

- Aerospace Industry: Employed in parts demanding high tensile strength and corrosion resistance.

- Electronics: Used in components requiring high mechanical properties and corrosion resistance, such as casings and accessories.

- Consumer Goods Industry: Manufacturing products like cutlery, kitchen tools, and other items requiring high durability.

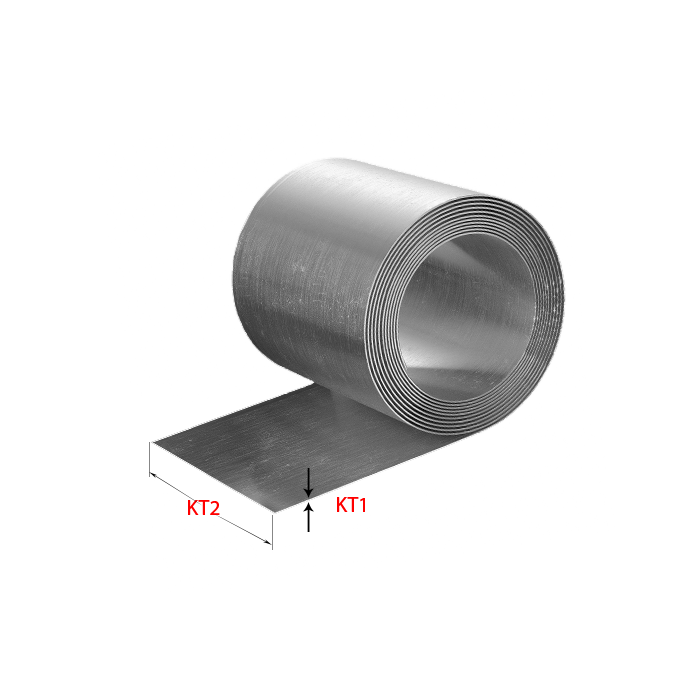

- Shape and Size:

- SUS 301 CSP stainless steel is commonly available in coil, sheet, or wire forms, with dimensions and thicknesses depending on the specific requirements of the application.

Manufacturing and Processing:

- SUS 301 CSP is typically produced through modern metallurgical processes, including cold working or cold rolling, to enhance the strength and hardness of the steel.

(Source: Internet)

Key Characteristics of SUS 301 CSP Stainless Steel:

- Chemical Composition:

- Carbon (C): Maximum 0.15%, enhances tensile strength and hardness.

- Chromium (Cr): 16.0-18.0%, provides corrosion and oxidation resistance.

- Nickel (Ni): 6.0-8.0%, improves mechanical properties and corrosion resistance.

- Manganese (Mn): Maximum 2.0%, enhances the steel's machinability.

- Silicon (Si): Maximum 1.0%, contributes to strength and hardness.

- Physical Properties:

- Tensile Strength: SUS 301 CSP has high tensile strength, ranging from approximately 930-1100 MPa, depending on the processing state.

- Ductility: Offers good formability for bending, cutting, and shaping, thanks to its ductile nature.

- Corrosion Resistance: While not as corrosion-resistant as SUS 304, SUS 301 CSP still offers resistance to corrosion in mild and moderate environments.

- Hardness: Can achieve higher hardness through cold working, making it suitable for applications requiring high hardness and strength.

- Applications:

- Automotive Industry: Used in components requiring high strength and elasticity, such as springs, structural parts, and fasteners.

- Aerospace Industry: Employed in parts demanding high tensile strength and corrosion resistance.

- Electronics: Used in components requiring high mechanical properties and corrosion resistance, such as casings and accessories.

- Consumer Goods Industry: Manufacturing products like cutlery, kitchen tools, and other items requiring high durability.

- Shape and Size:

- SUS 301 CSP stainless steel is commonly available in coil, sheet, or wire forms, with dimensions and thicknesses depending on the specific requirements of the application.

Manufacturing and Processing:

- SUS 301 CSP is typically produced through modern metallurgical processes, including cold working or cold rolling, to enhance the strength and hardness of the steel.

(Source: Internet)