THÔNG TIN CƠ BẢN

S50CF Non-Alloy Steel is an improved version of S50C steel, designed to enhance certain mechanical properties and machinability. S50CF retains the fundamental characteristics of medium carbon steel but is optimized for applications requiring higher strength and more stable hardness.

Key Characteristics of S50CF Non-Alloy Steel:

- Chemical Composition:

- Carbon (C): Approximately 0.47% - 0.53%

- Manganese (Mn): Approximately 0.60% - 0.90%

- Silicon (Si): Approximately 0.15% - 0.35%

- Phosphorus (P): Max 0.030%

- Sulfur (S): Max 0.030%

- Iron (Fe): The remainder

- Physical Properties:

- High Tensile Strength: S50CF has higher tensile strength and hardness compared to standard S50C, enhancing the material's load-bearing capacity.

- Stable Hardness: Optimized to maintain stable hardness after heat treatment.

- Good Machinability: S50CF retains good machinability, suitable for high-precision applications.

- Applications:

- Mold and Tool Manufacturing: Widely used in the manufacturing of molds, cutting tools, and high-load machine components.

- Machinery Manufacturing: Used in mechanical parts requiring high strength and precision, such as shafts, gears, and other load-bearing components.

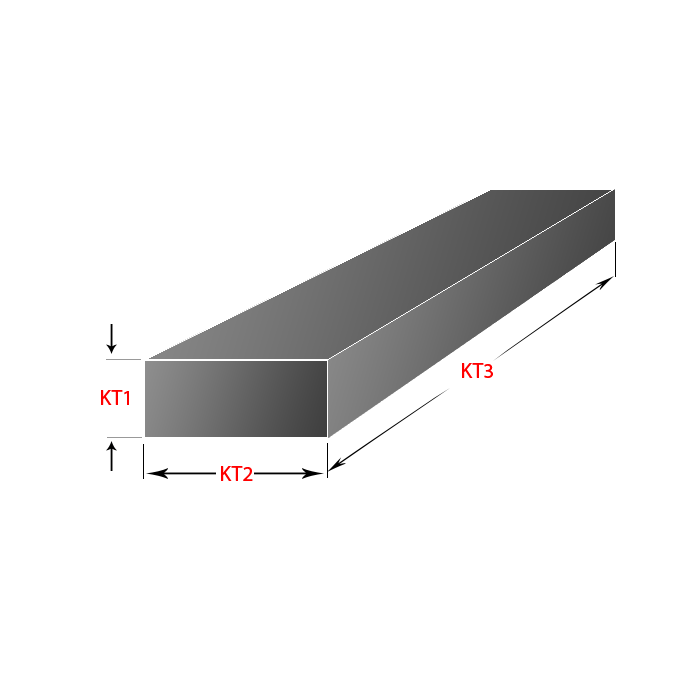

- Shape and Size:

- S50CF steel is typically supplied in plate, bar, or other product forms according to specific requirements.

Manufacturing and Processing:

- S50CF is produced using advanced steelmaking processes combined with heat treatment methods to optimize mechanical properties. Hot rolling and heat treatment are conducted to achieve the desired strength and hardness.

(Source: Internet)

Key Characteristics of S50CF Non-Alloy Steel:

- Chemical Composition:

- Carbon (C): Approximately 0.47% - 0.53%

- Manganese (Mn): Approximately 0.60% - 0.90%

- Silicon (Si): Approximately 0.15% - 0.35%

- Phosphorus (P): Max 0.030%

- Sulfur (S): Max 0.030%

- Iron (Fe): The remainder

- Physical Properties:

- High Tensile Strength: S50CF has higher tensile strength and hardness compared to standard S50C, enhancing the material's load-bearing capacity.

- Stable Hardness: Optimized to maintain stable hardness after heat treatment.

- Good Machinability: S50CF retains good machinability, suitable for high-precision applications.

- Applications:

- Mold and Tool Manufacturing: Widely used in the manufacturing of molds, cutting tools, and high-load machine components.

- Machinery Manufacturing: Used in mechanical parts requiring high strength and precision, such as shafts, gears, and other load-bearing components.

- Shape and Size:

- S50CF steel is typically supplied in plate, bar, or other product forms according to specific requirements.

Manufacturing and Processing:

- S50CF is produced using advanced steelmaking processes combined with heat treatment methods to optimize mechanical properties. Hot rolling and heat treatment are conducted to achieve the desired strength and hardness.

(Source: Internet)