THÔNG TIN CƠ BẢN

SUS 304 HL Stainless Steel is a type of austenitic stainless steel known for its good corrosion resistance and ease of processing. The “HL” designation typically refers to the “Hairline” surface finish, which features fine, linear patterns, providing an attractive decorative effect.

Key Characteristics of SUS 304 HL Stainless Steel:

- Chemical Composition:

- Carbon (C): Max 0.08%

- Chromium (Cr): 18.00-20.00%

- Nickel (Ni): 8.00-10.50%

- Manganese (Mn): Max 2.00%

- Silicon (Si): Max 1.00%

- Phosphorus (P): Max 0.045%

- Sulfur (S): Max 0.030%

- Physical Properties:

- Corrosion Resistance: Good, due to the high chromium and nickel content. SUS 304 HL offers excellent corrosion resistance in various environments, including damp and mild chemical conditions.

- Strength and Ductility: High, with good mechanical properties allowing for ductility and strength.

- Surface Finish: The “Hairline” (HL) finish features fine, linear patterns that create an attractive decorative effect, making it popular for applications requiring both functional and aesthetic qualities.

- Applications:

- Construction Industry: Used in cladding and interior decoration due to its attractive HL finish and good corrosion resistance.

- Manufacturing: Applied in household appliances, industrial machinery, and medical equipment.

- Food and Pharmaceutical Industry: Often used in applications involving food and pharmaceuticals due to its excellent corrosion resistance and ease of cleaning.

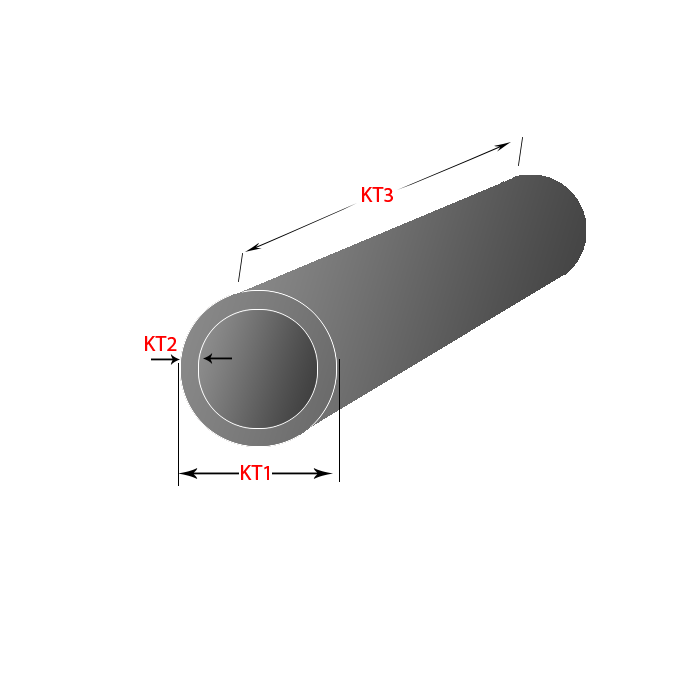

- Form and Size:

- SUS 304 HL is commonly available in sheets, coils, or custom-fabricated products based on application requirements.

Manufacturing and Processing:

- Production Process: SUS 304 HL is produced through hot rolling, cold rolling, and surface finishing processes to achieve the desired quality and appearance.

- Machining: Can be easily machined using methods such as cutting, welding, and stamping. The HL surface finish requires precise processing to maintain both aesthetic and functional qualities.

(Source: Internet)

Key Characteristics of SUS 304 HL Stainless Steel:

- Chemical Composition:

- Carbon (C): Max 0.08%

- Chromium (Cr): 18.00-20.00%

- Nickel (Ni): 8.00-10.50%

- Manganese (Mn): Max 2.00%

- Silicon (Si): Max 1.00%

- Phosphorus (P): Max 0.045%

- Sulfur (S): Max 0.030%

- Physical Properties:

- Corrosion Resistance: Good, due to the high chromium and nickel content. SUS 304 HL offers excellent corrosion resistance in various environments, including damp and mild chemical conditions.

- Strength and Ductility: High, with good mechanical properties allowing for ductility and strength.

- Surface Finish: The “Hairline” (HL) finish features fine, linear patterns that create an attractive decorative effect, making it popular for applications requiring both functional and aesthetic qualities.

- Applications:

- Construction Industry: Used in cladding and interior decoration due to its attractive HL finish and good corrosion resistance.

- Manufacturing: Applied in household appliances, industrial machinery, and medical equipment.

- Food and Pharmaceutical Industry: Often used in applications involving food and pharmaceuticals due to its excellent corrosion resistance and ease of cleaning.

- Form and Size:

- SUS 304 HL is commonly available in sheets, coils, or custom-fabricated products based on application requirements.

Manufacturing and Processing:

- Production Process: SUS 304 HL is produced through hot rolling, cold rolling, and surface finishing processes to achieve the desired quality and appearance.

- Machining: Can be easily machined using methods such as cutting, welding, and stamping. The HL surface finish requires precise processing to maintain both aesthetic and functional qualities.

(Source: Internet)