THÔNG TIN CƠ BẢN

Aluminum Alloy A1050 is a high-purity aluminum alloy in the 1000 series, with a purity level of 99.5% aluminum. A1050 is known for its excellent electrical and thermal conductivity, high corrosion resistance, and outstanding ductility. This alloy is commonly used in applications that require high purity and electrical conductivity but do not require high mechanical strength.

Key Characteristics of Aluminum Alloy A1050:

- Chemical Composition:

- A1050 primarily consists of aluminum (Al) with a purity of 99.5%, along with small amounts of impurities such as iron (Fe) and silicon (Si).

- Physical Properties:

- Excellent Electrical and Thermal Conductivity: With high purity, A1050 offers excellent electrical and thermal conductivity, second only to pure 1000 aluminum.

- Corrosion Resistance: A1050 has good corrosion resistance, particularly in air, fresh water, and some mild chemicals.

- High Ductility: A1050 is highly ductile, making it easy to roll, bend, and draw into various forms.

- Low Mechanical Strength: A1050 has lower mechanical strength compared to other aluminum alloys, making it more suitable for applications not requiring high load-bearing capacity.

- Applications:

- Electrical and Electronics Industry: Used in the production of electrical conductors, capacitors, and other electronic components due to its high electrical conductivity.

- Food Packaging: Utilized in food packaging materials, foil, due to its corrosion resistance and non-toxic properties.

- Construction and Decoration: Employed in building materials and interior decoration products due to its ease of fabrication and bright surface finish.

- Household Items: Used in household products such as cookware, pans, and other kitchen appliances.

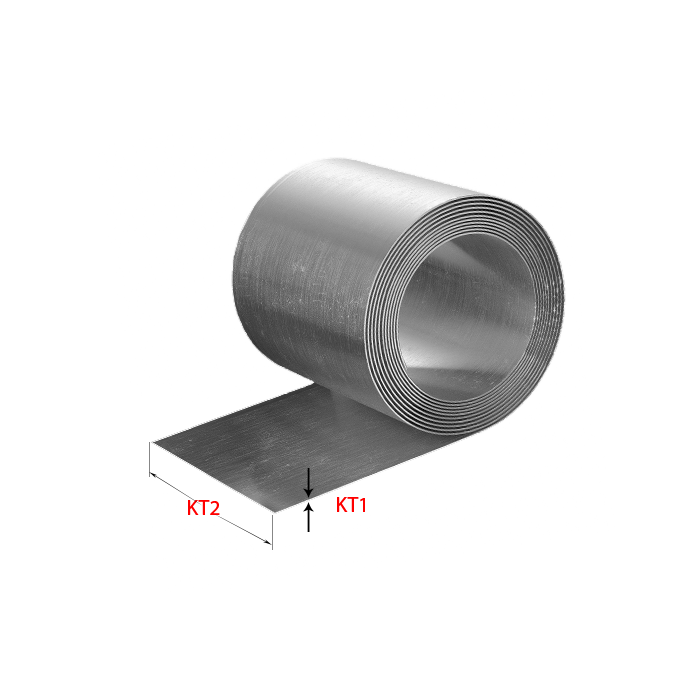

- Shape and Size:

- A1050 aluminum is commonly supplied in forms such as sheets, coils, or wires, and can be fabricated into various shapes depending on the application requirements.

Manufacturing and Processing:

- A1050 aluminum is produced through hot and cold rolling processes to achieve the desired thickness and shape. It can be easily processed using methods such as welding, cutting, and bending.

(Source: Internet)

Key Characteristics of Aluminum Alloy A1050:

- Chemical Composition:

- A1050 primarily consists of aluminum (Al) with a purity of 99.5%, along with small amounts of impurities such as iron (Fe) and silicon (Si).

- Physical Properties:

- Excellent Electrical and Thermal Conductivity: With high purity, A1050 offers excellent electrical and thermal conductivity, second only to pure 1000 aluminum.

- Corrosion Resistance: A1050 has good corrosion resistance, particularly in air, fresh water, and some mild chemicals.

- High Ductility: A1050 is highly ductile, making it easy to roll, bend, and draw into various forms.

- Low Mechanical Strength: A1050 has lower mechanical strength compared to other aluminum alloys, making it more suitable for applications not requiring high load-bearing capacity.

- Applications:

- Electrical and Electronics Industry: Used in the production of electrical conductors, capacitors, and other electronic components due to its high electrical conductivity.

- Food Packaging: Utilized in food packaging materials, foil, due to its corrosion resistance and non-toxic properties.

- Construction and Decoration: Employed in building materials and interior decoration products due to its ease of fabrication and bright surface finish.

- Household Items: Used in household products such as cookware, pans, and other kitchen appliances.

- Shape and Size:

- A1050 aluminum is commonly supplied in forms such as sheets, coils, or wires, and can be fabricated into various shapes depending on the application requirements.

Manufacturing and Processing:

- A1050 aluminum is produced through hot and cold rolling processes to achieve the desired thickness and shape. It can be easily processed using methods such as welding, cutting, and bending.

(Source: Internet)