THÔNG TIN CƠ BẢN

C17200 Copper Alloy, also known as Beryllium Copper or Beryllium Bronze, is a type of copper alloy known for its high hardness, tensile strength, and fatigue resistance. This alloy has unique properties due to the combination of copper (Cu) and beryllium (Be), along with some other elements.

Key characteristics of C17200 Copper Alloy:

- Chemical Composition:

- C17200 typically contains about 1.8-2% Beryllium (Be) and small amounts of other elements like Cobalt (Co), with the balance being copper (Cu).

- Physical Properties:

- High Hardness and Strength: C17200 can achieve high hardness and excellent tensile strength after heat treatment, making it ideal for applications requiring durability.

- Fatigue Resistance: This alloy offers excellent fatigue resistance, extending the lifespan of components made from C17200 under continuous operation.

- Electrical and Thermal Conductivity: Although not as conductive as pure copper, C17200 still offers good electrical and thermal conductivity.

- Chemical Properties:

- Corrosion Resistance: C17200 provides good corrosion resistance in harsh environments, including those containing chemicals and salts.

- Applications:

- Electronics Industry: Used in contact springs, connectors, and electronic components requiring high strength and conductivity.

- Aerospace Industry: Employed in components requiring high hardness, strength, and fatigue resistance.

- Oil and Gas Industry: Used in valve components, springs, and high-load-bearing equipment in extreme environments.

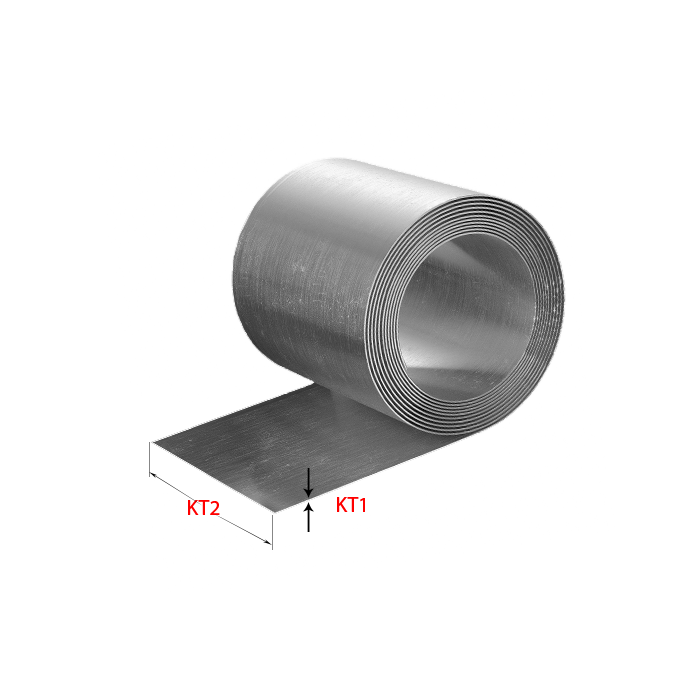

- Shape and Size:

- C17200 copper alloy is typically available in forms such as sheets, bars, tubes, and coils, suitable for various applications.

Manufacturing and Processing:

- C17200 is produced through complex metallurgical and heat treatment processes to achieve the desired mechanical properties. These processes are tightly controlled to ensure product quality.

(Source: Internet)

Key characteristics of C17200 Copper Alloy:

- Chemical Composition:

- C17200 typically contains about 1.8-2% Beryllium (Be) and small amounts of other elements like Cobalt (Co), with the balance being copper (Cu).

- Physical Properties:

- High Hardness and Strength: C17200 can achieve high hardness and excellent tensile strength after heat treatment, making it ideal for applications requiring durability.

- Fatigue Resistance: This alloy offers excellent fatigue resistance, extending the lifespan of components made from C17200 under continuous operation.

- Electrical and Thermal Conductivity: Although not as conductive as pure copper, C17200 still offers good electrical and thermal conductivity.

- Chemical Properties:

- Corrosion Resistance: C17200 provides good corrosion resistance in harsh environments, including those containing chemicals and salts.

- Applications:

- Electronics Industry: Used in contact springs, connectors, and electronic components requiring high strength and conductivity.

- Aerospace Industry: Employed in components requiring high hardness, strength, and fatigue resistance.

- Oil and Gas Industry: Used in valve components, springs, and high-load-bearing equipment in extreme environments.

- Shape and Size:

- C17200 copper alloy is typically available in forms such as sheets, bars, tubes, and coils, suitable for various applications.

Manufacturing and Processing:

- C17200 is produced through complex metallurgical and heat treatment processes to achieve the desired mechanical properties. These processes are tightly controlled to ensure product quality.

(Source: Internet)