THÔNG TIN CƠ BẢN

C3604BD Copper Alloy, also known as Brass 360 or Free-Cutting Brass, is a copper alloy containing zinc (Zn) and lead (Pb), known for its excellent machinability and high strength. This alloy is commonly used in applications requiring precision machining, such as the manufacture of mechanical parts and electronic components.

Key characteristics of C3604BD Copper Alloy:

- Chemical Composition:

- C3604BD contains approximately 60-63% copper (Cu), 35-37% zinc (Zn), and a small amount of lead (Pb) ranging from 2.5-3.7%. The lead content enhances machinability without significantly affecting the mechanical properties of the alloy.

- Physical Properties:

- Excellent Machinability: Due to its lead content, C3604BD offers superior machinability, reducing tool wear and increasing productivity during the machining process.

- Good Strength and Hardness: This alloy has good strength and hardness, making it suitable for a variety of engineering and mechanical applications.

- Corrosion Resistance: C3604BD has good corrosion resistance in many environments, although it may be affected by strong acidic or alkaline environments.

- Applications:

- Mechanical Engineering: Used in the production of mechanical parts such as gears, shafts, and other machine components, thanks to its easy machinability and high precision.

- Electronics Industry: Applied in the manufacture of electronic components and connectors due to its good electrical conductivity and precision machining capabilities.

- Valve and Fittings Manufacturing: Used in the production of valves, pipe fittings, and other accessories due to its corrosion resistance and mechanical strength.

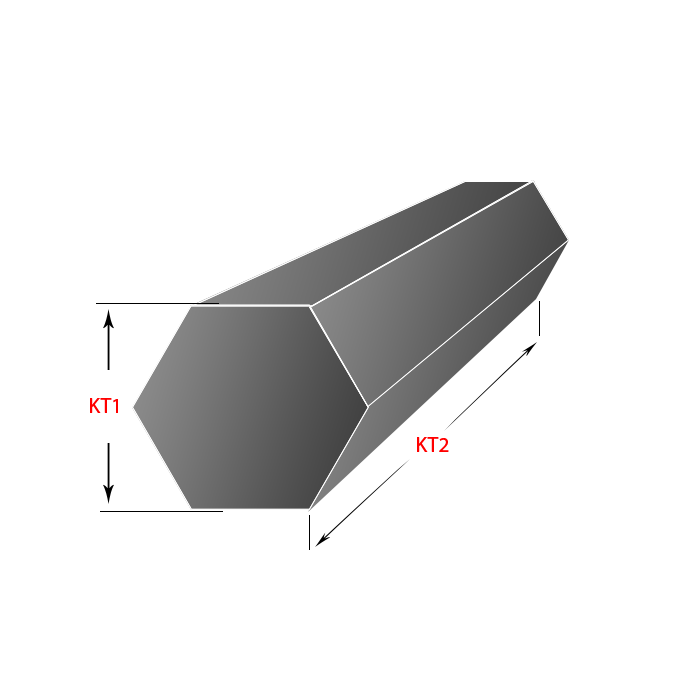

- Shape and Size:

- C3604BD copper alloy is typically available in the form of rods, tubes, or wires, catering to various industrial needs.

Manufacturing and Processing:

- C3604BD is produced through casting and rolling processes, followed by further machining using methods such as cutting, turning, and stamping. Its excellent machinability helps reduce costs and increase production efficiency.

(Source: Internet)

Key characteristics of C3604BD Copper Alloy:

- Chemical Composition:

- C3604BD contains approximately 60-63% copper (Cu), 35-37% zinc (Zn), and a small amount of lead (Pb) ranging from 2.5-3.7%. The lead content enhances machinability without significantly affecting the mechanical properties of the alloy.

- Physical Properties:

- Excellent Machinability: Due to its lead content, C3604BD offers superior machinability, reducing tool wear and increasing productivity during the machining process.

- Good Strength and Hardness: This alloy has good strength and hardness, making it suitable for a variety of engineering and mechanical applications.

- Corrosion Resistance: C3604BD has good corrosion resistance in many environments, although it may be affected by strong acidic or alkaline environments.

- Applications:

- Mechanical Engineering: Used in the production of mechanical parts such as gears, shafts, and other machine components, thanks to its easy machinability and high precision.

- Electronics Industry: Applied in the manufacture of electronic components and connectors due to its good electrical conductivity and precision machining capabilities.

- Valve and Fittings Manufacturing: Used in the production of valves, pipe fittings, and other accessories due to its corrosion resistance and mechanical strength.

- Shape and Size:

- C3604BD copper alloy is typically available in the form of rods, tubes, or wires, catering to various industrial needs.

Manufacturing and Processing:

- C3604BD is produced through casting and rolling processes, followed by further machining using methods such as cutting, turning, and stamping. Its excellent machinability helps reduce costs and increase production efficiency.

(Source: Internet)