THÔNG TIN CƠ BẢN

C2801 Copper Alloy, also known as Brass, is an alloy composed of copper (Cu) and zinc (Zn), with a higher zinc content compared to some other brass alloys. This alloy is known for its high strength, good ductility, and corrosion resistance, making it widely used in various industrial applications.

Key characteristics of C2801 Copper Alloy:

- Chemical Composition:

- C2801 contains approximately 60-63% copper (Cu) and 37-40% zinc (Zn). This ratio provides the alloy with high strength and good wear resistance.

- Physical Properties:

- Strength and Hardness: C2801 has high tensile strength and good hardness, suitable for applications requiring durable materials.

- Ductility and Machinability: This alloy has good ductility, making it easy to process through methods such as pressing, stamping, and bending.

- Electrical and Thermal Conductivity: Although not as high as pure copper, C2801 still offers good electrical and thermal conductivity.

- Chemical Properties:

- Corrosion Resistance: C2801 provides good corrosion resistance in various environments, particularly in water and marine environments.

- Applications:

- Mechanical Engineering: Used in the production of machine parts such as screws, bolts, and other load-bearing components.

- Electrical and Electronics Industry: Used in electrical connectors, contacts, and electronic components.

- Interior Decoration and Architecture: Employed in interior fittings, doors, and architectural decorations due to its bright appearance and corrosion resistance.

- Tube Manufacturing: Used in the production of high-pressure tubes and water pipes in construction and industrial applications.

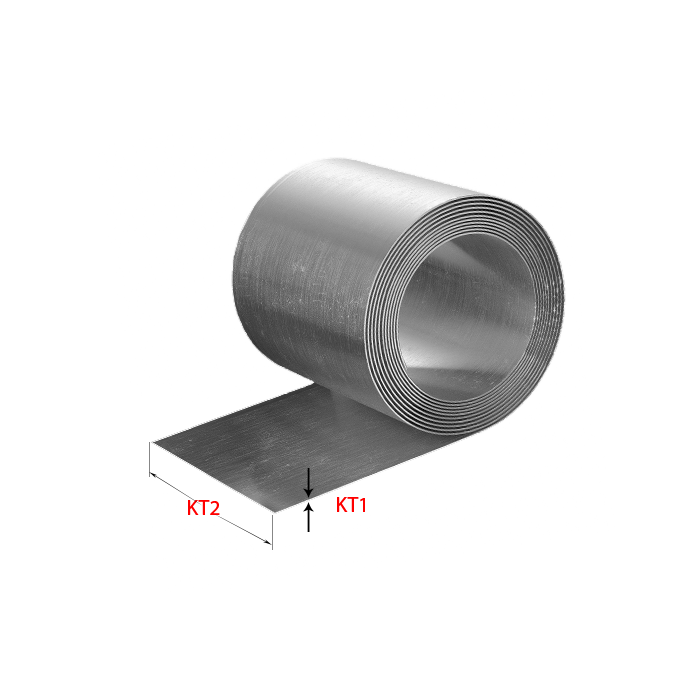

- Shape and Size:

- C2801 copper alloy is typically available in forms such as sheets, bars, tubes, and wires, suitable for various industrial applications.

Manufacturing and Processing:

- C2801 is produced through casting and rolling processes, followed by further machining processes such as cutting, stamping, and bending to create the final products.

(Source: Internet)

Key characteristics of C2801 Copper Alloy:

- Chemical Composition:

- C2801 contains approximately 60-63% copper (Cu) and 37-40% zinc (Zn). This ratio provides the alloy with high strength and good wear resistance.

- Physical Properties:

- Strength and Hardness: C2801 has high tensile strength and good hardness, suitable for applications requiring durable materials.

- Ductility and Machinability: This alloy has good ductility, making it easy to process through methods such as pressing, stamping, and bending.

- Electrical and Thermal Conductivity: Although not as high as pure copper, C2801 still offers good electrical and thermal conductivity.

- Chemical Properties:

- Corrosion Resistance: C2801 provides good corrosion resistance in various environments, particularly in water and marine environments.

- Applications:

- Mechanical Engineering: Used in the production of machine parts such as screws, bolts, and other load-bearing components.

- Electrical and Electronics Industry: Used in electrical connectors, contacts, and electronic components.

- Interior Decoration and Architecture: Employed in interior fittings, doors, and architectural decorations due to its bright appearance and corrosion resistance.

- Tube Manufacturing: Used in the production of high-pressure tubes and water pipes in construction and industrial applications.

- Shape and Size:

- C2801 copper alloy is typically available in forms such as sheets, bars, tubes, and wires, suitable for various industrial applications.

Manufacturing and Processing:

- C2801 is produced through casting and rolling processes, followed by further machining processes such as cutting, stamping, and bending to create the final products.

(Source: Internet)