THÔNG TIN CƠ BẢN

C5210HQ Copper Alloy is a special variant of Phosphor Bronze C5210, distinguished by its high hardness and excellent elasticity. C5210HQ has been enhanced to meet more stringent technical requirements in industrial and electronic applications, particularly for products requiring exceptional precision and mechanical strength.

Key characteristics of C5210HQ Copper Alloy:

- Chemical Composition:

- C5210HQ contains approximately 7-9% tin (Sn), a small amount of phosphorus (P), with the remainder being copper (Cu). This composition provides the alloy with high hardness and enhanced corrosion resistance.

- Physical Properties:

- High Hardness: C5210HQ exhibits superior hardness and tensile strength, making it capable of withstanding significant loads with minimal deformation.

- Good Elasticity: The elasticity of C5210HQ is improved, making it suitable for applications requiring flexibility and high resilience.

- Electrical and Thermal Conductivity: C5210HQ maintains good electrical and thermal conductivity, making it suitable for applications requiring efficient transmission.

- Chemical Properties:

- Corrosion Resistance: C5210HQ offers excellent corrosion resistance in various environments, particularly in highly corrosive conditions such as marine environments.

- Applications:

- Electrical and Electronics Industry: Used in electronic components, connectors, and electrical contacts requiring high durability and stability.

- Spring and Elastic Component Manufacturing: C5210HQ is commonly used for producing springs and components requiring high elasticity and load-bearing capacity.

- Automotive and Aerospace Industries: Used in components requiring high precision and wear resistance.

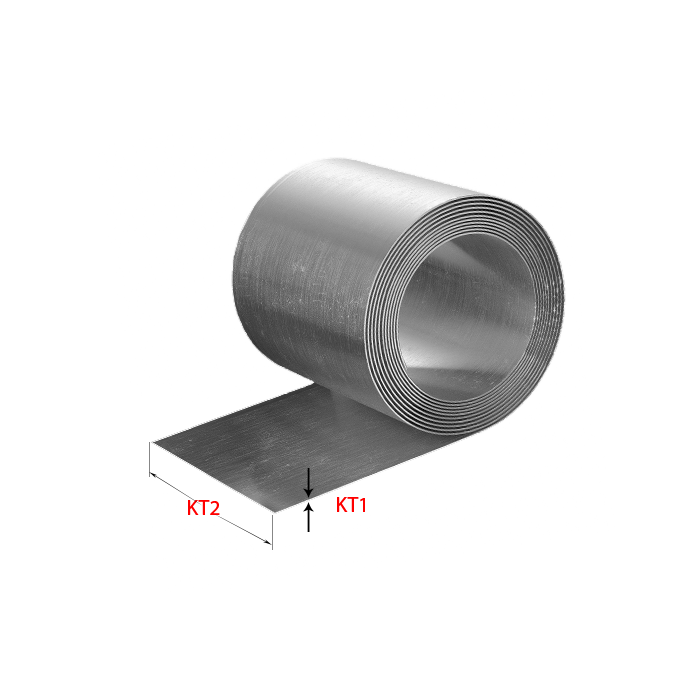

- Shape and Size:

- C5210HQ copper alloy is typically available in forms such as sheets, wires, or bars, suitable for various industrial applications.

Manufacturing and Processing:

- C5210HQ is produced through casting, rolling, and special heat treatment processes to achieve the desired mechanical properties. It can then be further processed through methods such as cutting, stamping, and bending.

(Source: Internet)

Key characteristics of C5210HQ Copper Alloy:

- Chemical Composition:

- C5210HQ contains approximately 7-9% tin (Sn), a small amount of phosphorus (P), with the remainder being copper (Cu). This composition provides the alloy with high hardness and enhanced corrosion resistance.

- Physical Properties:

- High Hardness: C5210HQ exhibits superior hardness and tensile strength, making it capable of withstanding significant loads with minimal deformation.

- Good Elasticity: The elasticity of C5210HQ is improved, making it suitable for applications requiring flexibility and high resilience.

- Electrical and Thermal Conductivity: C5210HQ maintains good electrical and thermal conductivity, making it suitable for applications requiring efficient transmission.

- Chemical Properties:

- Corrosion Resistance: C5210HQ offers excellent corrosion resistance in various environments, particularly in highly corrosive conditions such as marine environments.

- Applications:

- Electrical and Electronics Industry: Used in electronic components, connectors, and electrical contacts requiring high durability and stability.

- Spring and Elastic Component Manufacturing: C5210HQ is commonly used for producing springs and components requiring high elasticity and load-bearing capacity.

- Automotive and Aerospace Industries: Used in components requiring high precision and wear resistance.

- Shape and Size:

- C5210HQ copper alloy is typically available in forms such as sheets, wires, or bars, suitable for various industrial applications.

Manufacturing and Processing:

- C5210HQ is produced through casting, rolling, and special heat treatment processes to achieve the desired mechanical properties. It can then be further processed through methods such as cutting, stamping, and bending.

(Source: Internet)