THÔNG TIN CƠ BẢN

C2600 Copper Alloy is a special copper alloy, belonging to the group of copper alloys with copper as the main component and other alloying elements. It is commonly used in various industrial applications.

Key characteristics of C2600 Copper Alloy:

- Chemical Composition:

- C2600 primarily contains copper (Cu) with a percentage of around 99% and small amounts of other alloying elements such as zinc (Zn).

- C2600 is also known as a low zinc copper alloy.

- Physical Properties:

- Electrical Conductivity: C2600 has good electrical conductivity, although not as high as pure copper.

- Hardness and Strength: C2600 is harder and more durable than pure copper, due to the presence of zinc and other alloying elements.

- Machinability: This alloy has good machinability, making it easy to cut, cast, and weld.

- Chemical Properties:

- Corrosion Resistance: C2600 has good corrosion resistance in various environments, though not as high as other copper alloys like copper-nickel alloys.

- Stability: It has high stability and is less affected by environmental factors.

- Applications:

- Electronics and Electrical Industry: Used in electronic components, electrical contacts, and parts requiring good electrical conductivity.

- Mechanical and Manufacturing: Commonly used in manufacturing mechanical parts, machine components, and components requiring high strength.

- Construction: C2600 can also be used in some construction applications due to its durability and corrosion resistance.

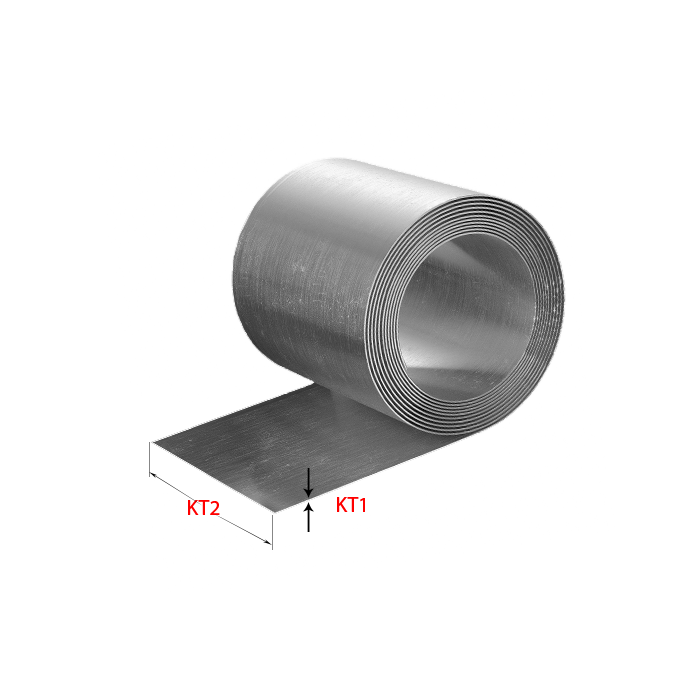

- Shape and Size:

- C2600 copper alloy is available in forms such as bars, sheets, coils, and custom shapes according to application requirements.

Manufacturing and Processing:

- C2600 copper alloy is produced through processes such as casting, rolling, and machining to create final products. This process involves adjusting the ratios of alloying elements to achieve the desired material properties.

(Source: Internet)

Key characteristics of C2600 Copper Alloy:

- Chemical Composition:

- C2600 primarily contains copper (Cu) with a percentage of around 99% and small amounts of other alloying elements such as zinc (Zn).

- C2600 is also known as a low zinc copper alloy.

- Physical Properties:

- Electrical Conductivity: C2600 has good electrical conductivity, although not as high as pure copper.

- Hardness and Strength: C2600 is harder and more durable than pure copper, due to the presence of zinc and other alloying elements.

- Machinability: This alloy has good machinability, making it easy to cut, cast, and weld.

- Chemical Properties:

- Corrosion Resistance: C2600 has good corrosion resistance in various environments, though not as high as other copper alloys like copper-nickel alloys.

- Stability: It has high stability and is less affected by environmental factors.

- Applications:

- Electronics and Electrical Industry: Used in electronic components, electrical contacts, and parts requiring good electrical conductivity.

- Mechanical and Manufacturing: Commonly used in manufacturing mechanical parts, machine components, and components requiring high strength.

- Construction: C2600 can also be used in some construction applications due to its durability and corrosion resistance.

- Shape and Size:

- C2600 copper alloy is available in forms such as bars, sheets, coils, and custom shapes according to application requirements.

Manufacturing and Processing:

- C2600 copper alloy is produced through processes such as casting, rolling, and machining to create final products. This process involves adjusting the ratios of alloying elements to achieve the desired material properties.

(Source: Internet)