THÔNG TIN CƠ BẢN

SK5 Carbon Steel is a high-carbon steel widely used in applications requiring high hardness and excellent wear resistance. SK5 is notable for its high hardness and stable mechanical properties.

Key Characteristics of SK5 Carbon Steel:

- Chemical Composition:

- Carbon (C): Approximately 0.60% - 0.75%

- Manganese (Mn): Approximately 0.60% - 0.90%

- Silicon (Si): Approximately 0.15% - 0.35%

- Iron (Fe): The remainder

- Physical Properties:

- High Hardness: SK5 steel has high hardness, making it suitable for applications requiring excellent wear resistance and long-lasting sharpness.

- Wear Resistance: With its high carbon content, SK5 offers good wear resistance, ideal for cutting tools and blades.

- Weldability and Machinability: SK5 can be welded and machined, but care must be taken with temperature and conditions to avoid reducing its mechanical properties.

- Applications:

- Cutting Tools: Widely used in the production of knives, saw blades, and cutting tools requiring sharpness and durability.

- Molds: Used to manufacture molds and dies due to its wear resistance and ability to maintain shape.

- Construction and Machinery: Applied in machinery and construction requiring high strength and wear resistance.

- Shape and Size:

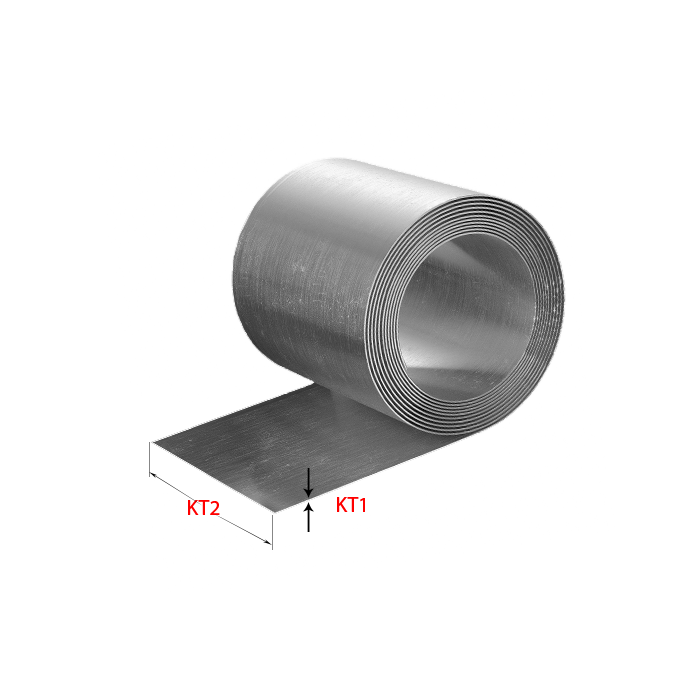

- SK5 steel is typically supplied in forms such as bars, plates, or coils depending on the specific application requirements.

Manufacturing and Processing:

- SK5 steel is produced through steelmaking and hot or cold rolling processes to achieve desired mechanical properties. It can then be heat-treated to improve hardness and mechanical properties.

(Source: Internet)

Key Characteristics of SK5 Carbon Steel:

- Chemical Composition:

- Carbon (C): Approximately 0.60% - 0.75%

- Manganese (Mn): Approximately 0.60% - 0.90%

- Silicon (Si): Approximately 0.15% - 0.35%

- Iron (Fe): The remainder

- Physical Properties:

- High Hardness: SK5 steel has high hardness, making it suitable for applications requiring excellent wear resistance and long-lasting sharpness.

- Wear Resistance: With its high carbon content, SK5 offers good wear resistance, ideal for cutting tools and blades.

- Weldability and Machinability: SK5 can be welded and machined, but care must be taken with temperature and conditions to avoid reducing its mechanical properties.

- Applications:

- Cutting Tools: Widely used in the production of knives, saw blades, and cutting tools requiring sharpness and durability.

- Molds: Used to manufacture molds and dies due to its wear resistance and ability to maintain shape.

- Construction and Machinery: Applied in machinery and construction requiring high strength and wear resistance.

- Shape and Size:

- SK5 steel is typically supplied in forms such as bars, plates, or coils depending on the specific application requirements.

Manufacturing and Processing:

- SK5 steel is produced through steelmaking and hot or cold rolling processes to achieve desired mechanical properties. It can then be heat-treated to improve hardness and mechanical properties.

(Source: Internet)