THÔNG TIN CƠ BẢN

Refined Copper C1100 is a high-purity copper known for its excellent electrical and thermal conductivity. Due to its high purity, C1100 is highly valued in applications that require good electrical conductivity and minimal impurities.

Key Characteristics of Refined Copper C1100:

- Chemical Composition:

- Alloy C1100 primarily consists of copper (Cu) with very high purity, typically above 99.9%, with almost no impurities or alloying elements.

- Physical Properties:

- Very High Electrical and Thermal Conductivity: C1100 has the highest electrical and thermal conductivity among copper alloys, making it the top choice for electrical and thermal applications.

- Ease of Fabrication: C1100 is very easy to machine, including processes like cutting, bending, and welding, facilitating the production of high-precision products.

- Corrosion Resistance: With high purity, C1100 also has good corrosion resistance, particularly in environments with minimal impurities.

- Applications:

- Electronics and Electrical Power: Widely used in the production of electrical wires, cables, conductive components, and heat sinks due to its high conductivity.

- Mechanical Industry: Used to manufacture mechanical components requiring excellent electrical and thermal conductivity as well as corrosion resistance.

- Construction: Often used in water piping systems, air conditioning systems, and other applications where electrical and thermal conductivity are important.

- Shape and Size:

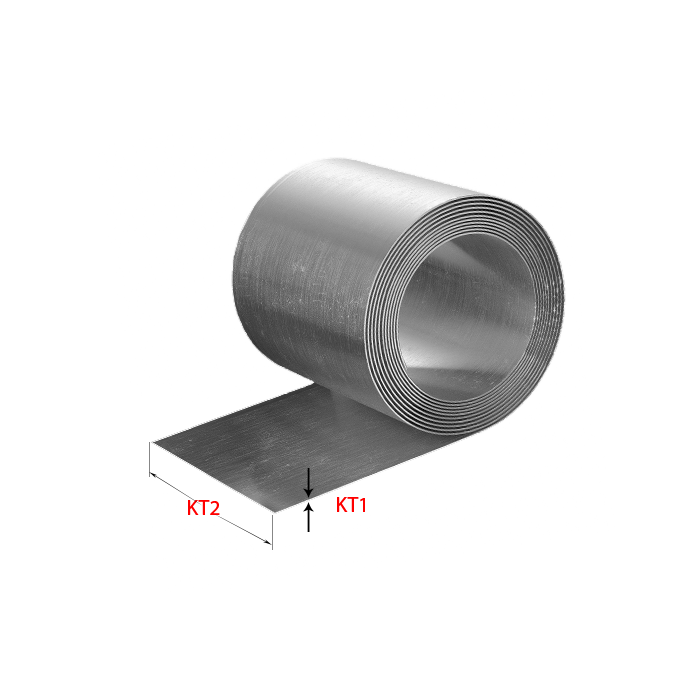

- Refined Copper C1100 is typically available in forms such as sheets, rods, tubes, and wires, depending on the application requirements.

Manufacturing and Processing:

- C1100 is produced through special refining processes to achieve high purity, and then machined to meet specific application needs.

(Source: Internet)

Key Characteristics of Refined Copper C1100:

- Chemical Composition:

- Alloy C1100 primarily consists of copper (Cu) with very high purity, typically above 99.9%, with almost no impurities or alloying elements.

- Physical Properties:

- Very High Electrical and Thermal Conductivity: C1100 has the highest electrical and thermal conductivity among copper alloys, making it the top choice for electrical and thermal applications.

- Ease of Fabrication: C1100 is very easy to machine, including processes like cutting, bending, and welding, facilitating the production of high-precision products.

- Corrosion Resistance: With high purity, C1100 also has good corrosion resistance, particularly in environments with minimal impurities.

- Applications:

- Electronics and Electrical Power: Widely used in the production of electrical wires, cables, conductive components, and heat sinks due to its high conductivity.

- Mechanical Industry: Used to manufacture mechanical components requiring excellent electrical and thermal conductivity as well as corrosion resistance.

- Construction: Often used in water piping systems, air conditioning systems, and other applications where electrical and thermal conductivity are important.

- Shape and Size:

- Refined Copper C1100 is typically available in forms such as sheets, rods, tubes, and wires, depending on the application requirements.

Manufacturing and Processing:

- C1100 is produced through special refining processes to achieve high purity, and then machined to meet specific application needs.

(Source: Internet)