THÔNG TIN CƠ BẢN

C2720 Copper Alloy, also known as Brass, is an alloy of copper (Cu) and zinc (Zn). It is one of the most common types of brass, widely used in various industries due to its diverse mechanical and chemical properties.

Key characteristics of C2720 Copper Alloy:

- Chemical Composition:

- C2720 typically contains about 62-65% copper (Cu) and 35-38% zinc (Zn), with small amounts of other elements to enhance the alloy's properties.

- Physical Properties:

- Ductility and Machinability: C2720 has high ductility, making it easy to work with through processes like stamping, pressing, and bending.

- Strength and Hardness: This alloy has good tensile strength and hardness, sufficient for general mechanical applications.

- Electrical and Thermal Conductivity: While not as high as pure copper, C2720 still offers good electrical and thermal conductivity.

- Chemical Properties:

- Corrosion Resistance: C2720 provides good corrosion resistance in various environments, particularly in water and steam.

- Applications:

- Mechanical Engineering: Used in the production of mechanical components such as bolts, nuts, and machine parts.

- Interior Decoration: Employed in making decorative items like door handles, lamps, and other decorative accessories due to its bright and attractive appearance.

- Music Industry: Used in the manufacture of wind instruments like brass horns, due to its ability to produce warm and resonant sounds.

- Electrical and Electronics Industry: Used in electronic components and electrical contacts.

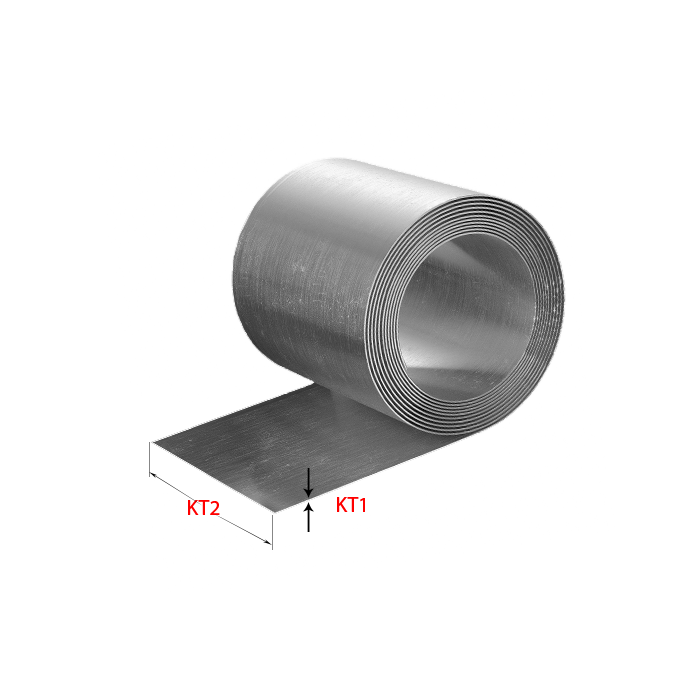

- Shape and Size:

- C2720 copper alloy is typically available in forms such as sheets, bars, tubes, or wires, suitable for various applications.

Manufacturing and Processing:

- C2720 is produced through casting and rolling processes, followed by further machining processes like cutting, stamping, and bending to create the final products.

(Source: Internet)

Key characteristics of C2720 Copper Alloy:

- Chemical Composition:

- C2720 typically contains about 62-65% copper (Cu) and 35-38% zinc (Zn), with small amounts of other elements to enhance the alloy's properties.

- Physical Properties:

- Ductility and Machinability: C2720 has high ductility, making it easy to work with through processes like stamping, pressing, and bending.

- Strength and Hardness: This alloy has good tensile strength and hardness, sufficient for general mechanical applications.

- Electrical and Thermal Conductivity: While not as high as pure copper, C2720 still offers good electrical and thermal conductivity.

- Chemical Properties:

- Corrosion Resistance: C2720 provides good corrosion resistance in various environments, particularly in water and steam.

- Applications:

- Mechanical Engineering: Used in the production of mechanical components such as bolts, nuts, and machine parts.

- Interior Decoration: Employed in making decorative items like door handles, lamps, and other decorative accessories due to its bright and attractive appearance.

- Music Industry: Used in the manufacture of wind instruments like brass horns, due to its ability to produce warm and resonant sounds.

- Electrical and Electronics Industry: Used in electronic components and electrical contacts.

- Shape and Size:

- C2720 copper alloy is typically available in forms such as sheets, bars, tubes, or wires, suitable for various applications.

Manufacturing and Processing:

- C2720 is produced through casting and rolling processes, followed by further machining processes like cutting, stamping, and bending to create the final products.

(Source: Internet)