THÔNG TIN CƠ BẢN

C5102 Copper Alloy, also known as Phosphor Bronze, is an alloy composed of copper (Cu) with tin (Sn) and a small amount of phosphorus (P). This alloy is well-known for its high strength, good elasticity, and corrosion resistance, making it suitable for various industrial applications that require high mechanical properties and stability.

Key characteristics of C5102 Copper Alloy:

- Chemical Composition:

- C5102 contains approximately 4.5-5.5% tin (Sn), a small amount of phosphorus (P), with the remainder being copper (Cu). The phosphorus enhances the alloy's hardness and strength while improving its wear resistance.

- Physical Properties:

- High Strength: C5102 has high tensile strength and good wear resistance, making it suitable for applications requiring durable and resilient materials.

- Good Elasticity: This alloy exhibits good elasticity, allowing it to return to its original shape after deformation, making it ideal for products such as springs.

- Electrical and Thermal Conductivity: While not as high as pure copper, C5102 still offers good electrical and thermal conductivity.

- Chemical Properties:

- Corrosion Resistance: C5102 provides excellent corrosion resistance in various environments, including marine conditions.

- Applications:

- Electrical and Electronics Industry: Used in electronic components, connectors, and electrical contacts due to its good conductivity and high tensile strength.

- Spring and Bearing Manufacturing: C5102 is commonly used for making springs, bearings, and other high-load mechanical components.

- Automotive and Aerospace Industries: Utilized in small parts requiring high strength and wear resistance.

- Music Industry: Used in manufacturing musical instruments such as strings, owing to its elasticity and durability.

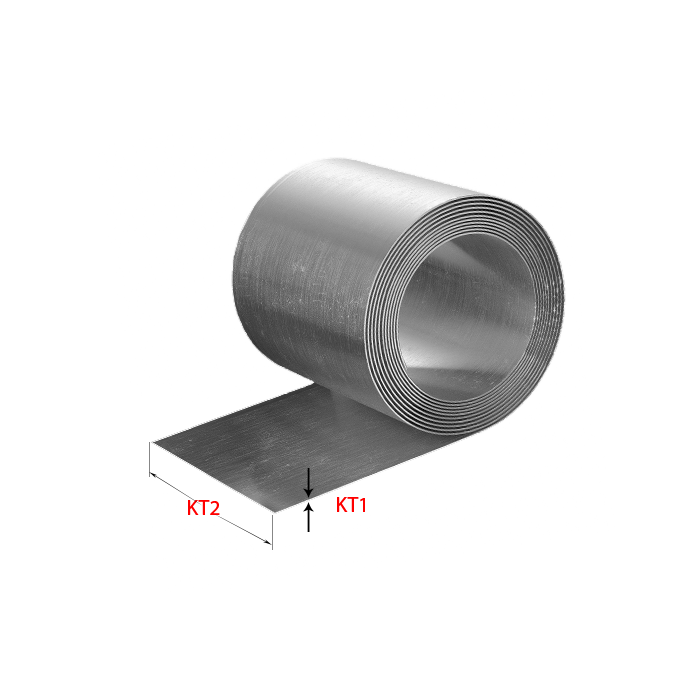

- Shape and Size:

- C5102 copper alloy is typically available in forms such as sheets, wires, bars, or tubes, suitable for various industrial applications.

Manufacturing and Processing:

- C5102 is produced through casting and rolling processes, followed by further machining processes such as cutting, stamping, and bending to create the final products.

(Source: Internet)

Key characteristics of C5102 Copper Alloy:

- Chemical Composition:

- C5102 contains approximately 4.5-5.5% tin (Sn), a small amount of phosphorus (P), with the remainder being copper (Cu). The phosphorus enhances the alloy's hardness and strength while improving its wear resistance.

- Physical Properties:

- High Strength: C5102 has high tensile strength and good wear resistance, making it suitable for applications requiring durable and resilient materials.

- Good Elasticity: This alloy exhibits good elasticity, allowing it to return to its original shape after deformation, making it ideal for products such as springs.

- Electrical and Thermal Conductivity: While not as high as pure copper, C5102 still offers good electrical and thermal conductivity.

- Chemical Properties:

- Corrosion Resistance: C5102 provides excellent corrosion resistance in various environments, including marine conditions.

- Applications:

- Electrical and Electronics Industry: Used in electronic components, connectors, and electrical contacts due to its good conductivity and high tensile strength.

- Spring and Bearing Manufacturing: C5102 is commonly used for making springs, bearings, and other high-load mechanical components.

- Automotive and Aerospace Industries: Utilized in small parts requiring high strength and wear resistance.

- Music Industry: Used in manufacturing musical instruments such as strings, owing to its elasticity and durability.

- Shape and Size:

- C5102 copper alloy is typically available in forms such as sheets, wires, bars, or tubes, suitable for various industrial applications.

Manufacturing and Processing:

- C5102 is produced through casting and rolling processes, followed by further machining processes such as cutting, stamping, and bending to create the final products.

(Source: Internet)