THÔNG TIN CƠ BẢN

Copper Alloy C6191 is a type of copper alloy known for its good wear resistance and high strength. This alloy is commonly used in industrial applications requiring a combination of mechanical properties and excellent corrosion resistance.

Key Characteristics of Copper Alloy C6191:

- Chemical Composition:

- Alloy C6191 primarily contains copper (Cu) with additional alloying elements such as aluminum (Al) and manganese (Mn) to enhance the alloy's strength and wear resistance.

- Physical Properties:

- Wear Resistance: C6191 offers good wear resistance, extending the lifespan of parts and tools.

- High Mechanical Strength: This alloy provides good mechanical strength, making it suitable for applications requiring high load-bearing capacity.

- Corrosion Resistance: C6191 has good corrosion resistance, particularly in humid or chemical environments.

- Electrical and Thermal Conductivity: While not as high as pure copper, C6191 maintains good electrical and thermal conductivity for electrical and thermal applications.

- Applications:

- Electronics and Electrical Power: Used in electrical components and conductors due to its good electrical conductivity and high strength.

- Mechanical Industry: Applied in the production of parts and tools requiring wear resistance and load-bearing capability.

- Chemical Industry: Suitable for applications in chemical environments due to its corrosion resistance.

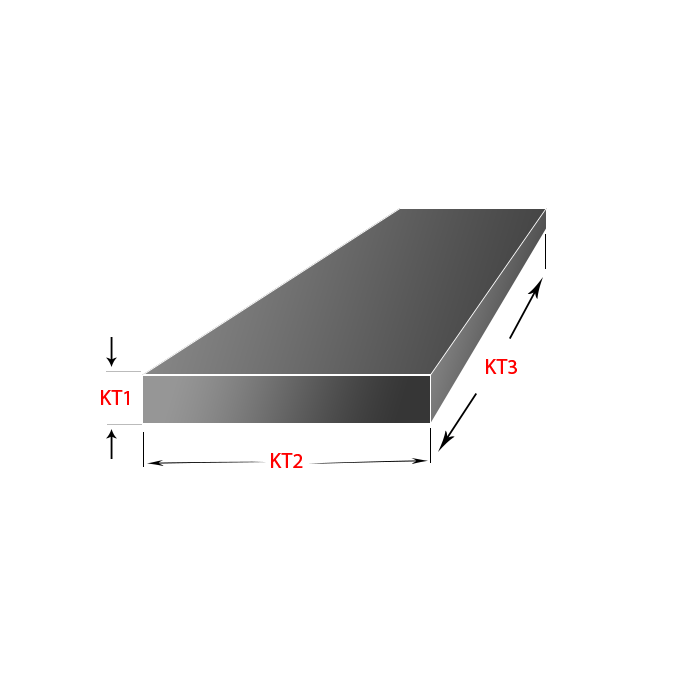

- Shape and Size:

- Copper Alloy C6191 is typically available in forms such as rods, plates, and other product forms based on specific application requirements.

Manufacturing and Processing:

- C6191 is produced through casting and machining processes. This alloy can be machined and welded depending on the specific requirements of the application.

(Source: Internet)

Key Characteristics of Copper Alloy C6191:

- Chemical Composition:

- Alloy C6191 primarily contains copper (Cu) with additional alloying elements such as aluminum (Al) and manganese (Mn) to enhance the alloy's strength and wear resistance.

- Physical Properties:

- Wear Resistance: C6191 offers good wear resistance, extending the lifespan of parts and tools.

- High Mechanical Strength: This alloy provides good mechanical strength, making it suitable for applications requiring high load-bearing capacity.

- Corrosion Resistance: C6191 has good corrosion resistance, particularly in humid or chemical environments.

- Electrical and Thermal Conductivity: While not as high as pure copper, C6191 maintains good electrical and thermal conductivity for electrical and thermal applications.

- Applications:

- Electronics and Electrical Power: Used in electrical components and conductors due to its good electrical conductivity and high strength.

- Mechanical Industry: Applied in the production of parts and tools requiring wear resistance and load-bearing capability.

- Chemical Industry: Suitable for applications in chemical environments due to its corrosion resistance.

- Shape and Size:

- Copper Alloy C6191 is typically available in forms such as rods, plates, and other product forms based on specific application requirements.

Manufacturing and Processing:

- C6191 is produced through casting and machining processes. This alloy can be machined and welded depending on the specific requirements of the application.

(Source: Internet)