THÔNG TIN CƠ BẢN

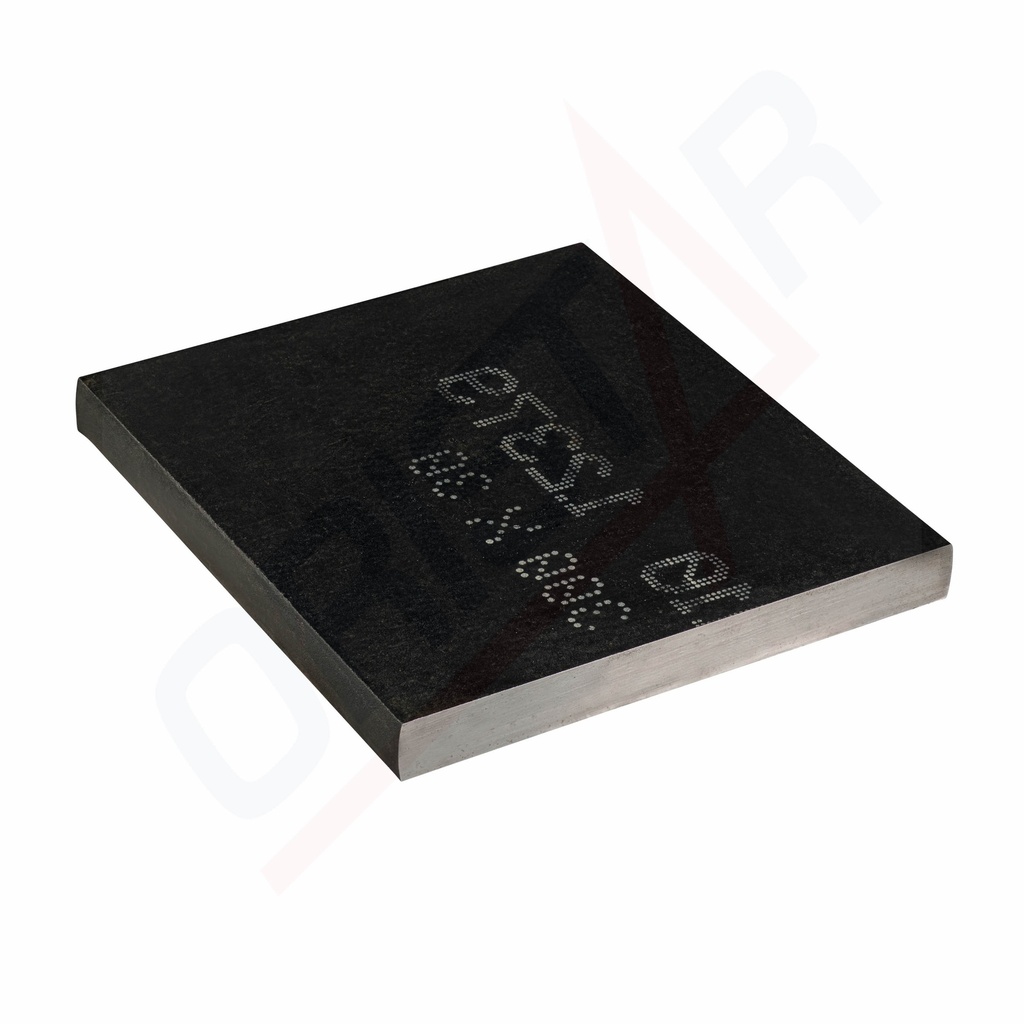

Alloy Steel Plate S600 is a specialized type of steel with high physical and mechanical properties, offering excellent wear and heat resistance. This steel belongs to the tool steel group and is designed to provide optimal performance under harsh load and wear conditions. Below is a detailed description of this steel:

1. Chemical Composition

Carbon (C): Increases hardness and strength after heat treatment.

Chromium (Cr): Enhances wear resistance, oxidation resistance, and improves heat resistance.

Molybdenum (Mo): Increases hardness, improves load-bearing capacity, and prevents cracking at high temperatures.

Vanadium (V): Improves strength and toughness, while also increasing wear resistance.

2. Mechanical Properties

Hardness: Can achieve high hardness after heat treatment, ranging from 58-62 HRC.

Tensile Strength: Very high, able to withstand large loads without deformation.

Wear Resistance: Excellent, particularly suitable for applications involving high friction and requiring long-lasting durability.

Heat Resistance: S600 maintains hardness and mechanical properties in high-temperature environments.

3. Applications

Cutting Tools: S600 is commonly used in manufacturing cutting tools such as drill bits, cutting blades, and stamping dies.

Molds: Widely used in the production of molds for the automotive and precision mechanical industries.

Heavy Industry: Applied in machine parts that endure heavy loads and heat, where high durability and wear resistance are required.

4. Heat Treatment

Quenching: The quenching process for S600 steel is typically performed at temperatures of around 1000-1100°C, followed by rapid cooling to achieve the desired hardness.

Tempering: After quenching, tempering is done to reduce brittleness and ensure dimensional stability. Tempering temperatures usually range from 500-600°C.

5. Key Advantages

Good machinability before heat treatment.

High durability and wear resistance after heat treatment.

Maintains hardness and mechanical properties at high temperatures.

S600 steel is an ideal choice for applications that require high load-bearing capacity and stable performance in harsh environments.

(Source: Internet)

1. Chemical Composition

Carbon (C): Increases hardness and strength after heat treatment.

Chromium (Cr): Enhances wear resistance, oxidation resistance, and improves heat resistance.

Molybdenum (Mo): Increases hardness, improves load-bearing capacity, and prevents cracking at high temperatures.

Vanadium (V): Improves strength and toughness, while also increasing wear resistance.

2. Mechanical Properties

Hardness: Can achieve high hardness after heat treatment, ranging from 58-62 HRC.

Tensile Strength: Very high, able to withstand large loads without deformation.

Wear Resistance: Excellent, particularly suitable for applications involving high friction and requiring long-lasting durability.

Heat Resistance: S600 maintains hardness and mechanical properties in high-temperature environments.

3. Applications

Cutting Tools: S600 is commonly used in manufacturing cutting tools such as drill bits, cutting blades, and stamping dies.

Molds: Widely used in the production of molds for the automotive and precision mechanical industries.

Heavy Industry: Applied in machine parts that endure heavy loads and heat, where high durability and wear resistance are required.

4. Heat Treatment

Quenching: The quenching process for S600 steel is typically performed at temperatures of around 1000-1100°C, followed by rapid cooling to achieve the desired hardness.

Tempering: After quenching, tempering is done to reduce brittleness and ensure dimensional stability. Tempering temperatures usually range from 500-600°C.

5. Key Advantages

Good machinability before heat treatment.

High durability and wear resistance after heat treatment.

Maintains hardness and mechanical properties at high temperatures.

S600 steel is an ideal choice for applications that require high load-bearing capacity and stable performance in harsh environments.

(Source: Internet)