THÔNG TIN CƠ BẢN

Aluminum Alloy A5052TD is an aluminum alloy from the 5000 series, known for its excellent corrosion resistance, high strength, and ease of fabrication. It is commonly used in applications requiring both mechanical properties and corrosion resistance, such as in construction, marine, and industrial sectors.

Key Characteristics of Aluminum Alloy A5052TD:

- Chemical Composition:

- A5052TD primarily consists of aluminum (Al) with key alloying elements including magnesium (2.2-2.8%) and a small amount of chromium (0.15-0.35%). This composition enhances the alloy’s corrosion resistance and mechanical strength.

- Physical Properties:

- Corrosion Resistance: A5052TD has excellent corrosion resistance, particularly in marine environments or humid conditions.

- Mechanical Strength: Provides good tensile strength and hardness, making it suitable for load-bearing applications.

- Ease of Machining: This alloy is easy to machine, weld, and process, making it suitable for various manufacturing methods.

- Applications:

- Construction: Used in exterior cladding panels, decorative structures, and other building applications.

- Marine Industry: Applied in boat parts and outdoor structures requiring corrosion resistance.

- Automotive Industry: Utilized in parts requiring high durability and corrosion resistance.

- Industrial Equipment: Used in manufacturing machinery components and industrial equipment requiring strength and corrosion resistance.

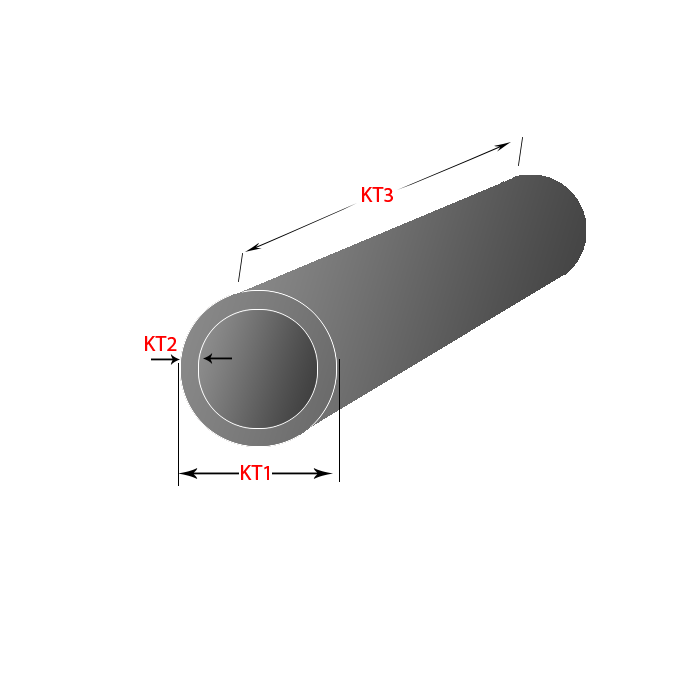

- Shape and Size:

- Aluminum Alloy A5052TD can be supplied in forms such as sheets, coils, bars, or custom products depending on specific application requirements.

Manufacturing and Processing:

- Aluminum Alloy A5052TD is typically produced through extrusion, rolling, and heat treatment processes to achieve desired mechanical properties. Fabrication processes include cutting, bending, and welding to meet specific technical requirements.

(Source: Internet)

Key Characteristics of Aluminum Alloy A5052TD:

- Chemical Composition:

- A5052TD primarily consists of aluminum (Al) with key alloying elements including magnesium (2.2-2.8%) and a small amount of chromium (0.15-0.35%). This composition enhances the alloy’s corrosion resistance and mechanical strength.

- Physical Properties:

- Corrosion Resistance: A5052TD has excellent corrosion resistance, particularly in marine environments or humid conditions.

- Mechanical Strength: Provides good tensile strength and hardness, making it suitable for load-bearing applications.

- Ease of Machining: This alloy is easy to machine, weld, and process, making it suitable for various manufacturing methods.

- Applications:

- Construction: Used in exterior cladding panels, decorative structures, and other building applications.

- Marine Industry: Applied in boat parts and outdoor structures requiring corrosion resistance.

- Automotive Industry: Utilized in parts requiring high durability and corrosion resistance.

- Industrial Equipment: Used in manufacturing machinery components and industrial equipment requiring strength and corrosion resistance.

- Shape and Size:

- Aluminum Alloy A5052TD can be supplied in forms such as sheets, coils, bars, or custom products depending on specific application requirements.

Manufacturing and Processing:

- Aluminum Alloy A5052TD is typically produced through extrusion, rolling, and heat treatment processes to achieve desired mechanical properties. Fabrication processes include cutting, bending, and welding to meet specific technical requirements.

(Source: Internet)