THÔNG TIN CƠ BẢN

C50715 Copper Alloy is a special copper alloy primarily composed of copper (Cu) and tin (Sn), also known as phosphor bronze. This alloy is known for its excellent corrosion resistance and high strength, making it suitable for a variety of industrial applications.

Key characteristics of C50715 Copper Alloy:

- Chemical Composition:

- C50715 contains approximately 88-90% copper (Cu) and 10-12% tin (Sn), along with trace amounts of other elements like phosphorus (P) to enhance the alloy’s physical properties.

- Physical Properties:

- Electrical and Thermal Conductivity: C50715 has good electrical and thermal conductivity, though lower than pure copper.

- Hardness and Strength: This alloy has high hardness and strength, making it ideal for applications requiring load-bearing and wear resistance.

- Machinability: C50715 can be easily processed through methods such as cutting, welding, and cold working.

- Chemical Properties:

- Corrosion Resistance: With its tin content, C50715 has excellent corrosion resistance, particularly in wet environments or when exposed to seawater.

- Stability: This alloy is highly stable and is minimally affected by environmental factors.

- Applications:

- Marine Industry: Used in marine equipment and components due to its corrosion resistance.

- Mechanical and Manufacturing: Commonly used in machinery parts, bushings, and bearings due to its wear resistance and load-bearing capabilities.

- Construction Industry: Employed in structures requiring long-term durability and corrosion resistance.

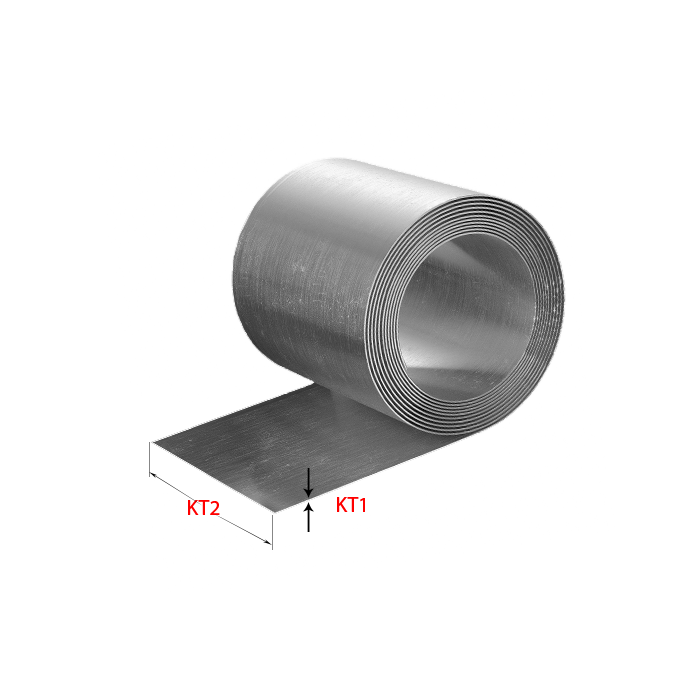

- Shape and Size:

- C50715 copper alloy is available in forms such as sheets, bars, tubes, and custom-fabricated products according to specific application needs.

Manufacturing and Processing:

- C50715 copper alloy is produced through processes such as casting, rolling, and machining to create final products, with a tightly controlled manufacturing process to ensure quality and consistency.

(Source: Internet)

Key characteristics of C50715 Copper Alloy:

- Chemical Composition:

- C50715 contains approximately 88-90% copper (Cu) and 10-12% tin (Sn), along with trace amounts of other elements like phosphorus (P) to enhance the alloy’s physical properties.

- Physical Properties:

- Electrical and Thermal Conductivity: C50715 has good electrical and thermal conductivity, though lower than pure copper.

- Hardness and Strength: This alloy has high hardness and strength, making it ideal for applications requiring load-bearing and wear resistance.

- Machinability: C50715 can be easily processed through methods such as cutting, welding, and cold working.

- Chemical Properties:

- Corrosion Resistance: With its tin content, C50715 has excellent corrosion resistance, particularly in wet environments or when exposed to seawater.

- Stability: This alloy is highly stable and is minimally affected by environmental factors.

- Applications:

- Marine Industry: Used in marine equipment and components due to its corrosion resistance.

- Mechanical and Manufacturing: Commonly used in machinery parts, bushings, and bearings due to its wear resistance and load-bearing capabilities.

- Construction Industry: Employed in structures requiring long-term durability and corrosion resistance.

- Shape and Size:

- C50715 copper alloy is available in forms such as sheets, bars, tubes, and custom-fabricated products according to specific application needs.

Manufacturing and Processing:

- C50715 copper alloy is produced through processes such as casting, rolling, and machining to create final products, with a tightly controlled manufacturing process to ensure quality and consistency.

(Source: Internet)