THÔNG TIN CƠ BẢN

C5191 Copper Alloy is a type of copper-tin phosphor bronze, known for its high mechanical strength, excellent corrosion resistance, and low friction characteristics, making it suitable for various industrial applications.

Key characteristics of C5191 Copper Alloy:

- Chemical Composition:

- C5191 contains approximately 93-95% copper (Cu), 4-6% tin (Sn), and a small amount of phosphorus (P) around 0.03-0.35%. Phosphorus enhances the alloy's mechanical properties and wear resistance.

- Physical Properties:

- High Strength: C5191 has high tensile strength and hardness, making it a good choice for load-bearing applications.

- Elasticity: This alloy has good elasticity, making it ideal for springs and elastic components.

- Electrical and Thermal Conductivity: Though lower than pure copper, C5191 still has decent electrical and thermal conductivity.

- Chemical Properties:

- Corrosion Resistance: C5191 offers excellent corrosion resistance, especially in environments exposed to water and mild chemicals.

- Wear Resistance: This alloy has good wear resistance, which helps extend the lifespan of components under harsh operating conditions.

- Applications:

- Electronics Industry: Used in electrical connectors, terminals, and electronic components due to its mechanical strength and elasticity.

- Mechanical Industry: Used in the production of springs, bearings, and other parts requiring high strength and wear resistance.

- Marine Industry: Employed in marine equipment due to its resistance to seawater corrosion.

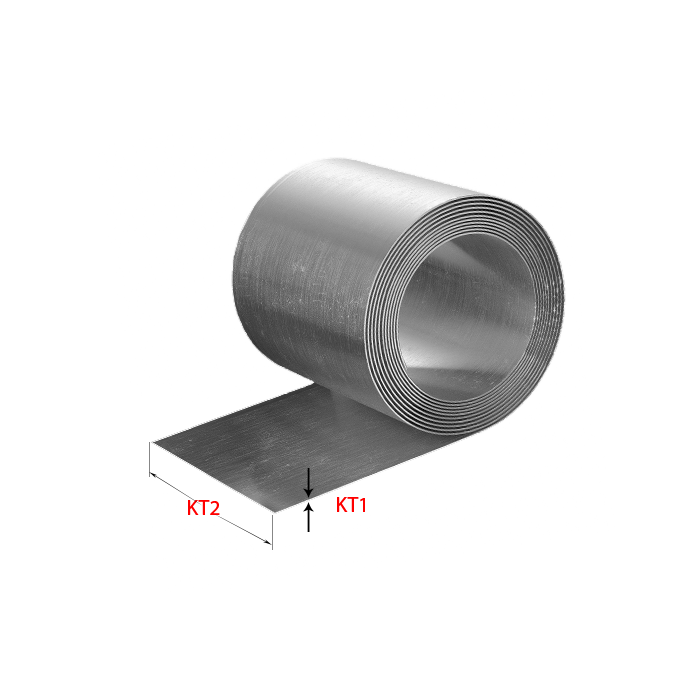

- Shape and Size:

- C5191 copper alloy is typically available in forms such as sheets, coils, bars, and other product forms depending on application requirements.

Manufacturing and Processing:

- C5191 copper alloy is produced through modern metallurgical processes such as casting, rolling, and cold working. The manufacturing process is tightly controlled to ensure the quality and performance of the final product.

(Source: Internet)

Key characteristics of C5191 Copper Alloy:

- Chemical Composition:

- C5191 contains approximately 93-95% copper (Cu), 4-6% tin (Sn), and a small amount of phosphorus (P) around 0.03-0.35%. Phosphorus enhances the alloy's mechanical properties and wear resistance.

- Physical Properties:

- High Strength: C5191 has high tensile strength and hardness, making it a good choice for load-bearing applications.

- Elasticity: This alloy has good elasticity, making it ideal for springs and elastic components.

- Electrical and Thermal Conductivity: Though lower than pure copper, C5191 still has decent electrical and thermal conductivity.

- Chemical Properties:

- Corrosion Resistance: C5191 offers excellent corrosion resistance, especially in environments exposed to water and mild chemicals.

- Wear Resistance: This alloy has good wear resistance, which helps extend the lifespan of components under harsh operating conditions.

- Applications:

- Electronics Industry: Used in electrical connectors, terminals, and electronic components due to its mechanical strength and elasticity.

- Mechanical Industry: Used in the production of springs, bearings, and other parts requiring high strength and wear resistance.

- Marine Industry: Employed in marine equipment due to its resistance to seawater corrosion.

- Shape and Size:

- C5191 copper alloy is typically available in forms such as sheets, coils, bars, and other product forms depending on application requirements.

Manufacturing and Processing:

- C5191 copper alloy is produced through modern metallurgical processes such as casting, rolling, and cold working. The manufacturing process is tightly controlled to ensure the quality and performance of the final product.

(Source: Internet)