THÔNG TIN CƠ BẢN

SUS 316L Stainless Steel Coil is an austenitic stainless steel with a higher molybdenum content than SUS 304, which enhances its corrosion resistance, especially in environments containing chlorides and other corrosive chemicals. SUS 316L is the low-carbon version of SUS 316, reducing the risk of intergranular corrosion after welding or when used in high-temperature environments.

Key Characteristics of SUS 316L Stainless Steel Coil:

- Chemical Composition:

- Chromium (Cr): 16.0-18.0%, provides corrosion and oxidation resistance.

- Nickel (Ni): 10.0-14.0%, enhances corrosion resistance and ductility.

- Molybdenum (Mo): 2.0-3.0%, improves corrosion resistance in chloride and chemical environments.

- Carbon (C): Maximum 0.03%, reduces susceptibility to intergranular corrosion.

- Manganese (Mn): Maximum 2.0%, improves machinability.

- Silicon (Si): Maximum 1.0%, contributes to strength and corrosion resistance.

- Phosphorus (P) and Sulfur (S): Both are present in maximum amounts of 0.045% and 0.030% respectively, maintaining high steel purity.

- Physical Properties:

- High Corrosion Resistance: Due to the high molybdenum content, SUS 316L offers better corrosion resistance compared to SUS 304, particularly in seawater, chloride-containing water, and corrosive chemical environments.

- High Ductility and Strength: It has good tensile strength and ductility, making it easy to process and form.

- Oxidation Resistance: Good in high-temperature environments but not recommended for prolonged use above 800°C.

- Good Weldability: The low carbon content minimizes carbide precipitation during welding, reducing the risk of intergranular corrosion after welding.

- Applications:

- Chemical and Petrochemical Industry: Used in equipment and pipelines for transporting chemicals where high corrosion resistance is required.

- Marine Industry: Used in ship structures, machinery parts exposed to seawater, and marine environments.

- Medical and Food Processing Equipment: Used in manufacturing medical instruments, food processing equipment due to its corrosion resistance and ease of cleaning.

- Construction Industry: Used in exterior applications and architecture where long-term durability and corrosion resistance are required.

Manufacturing and Processing:

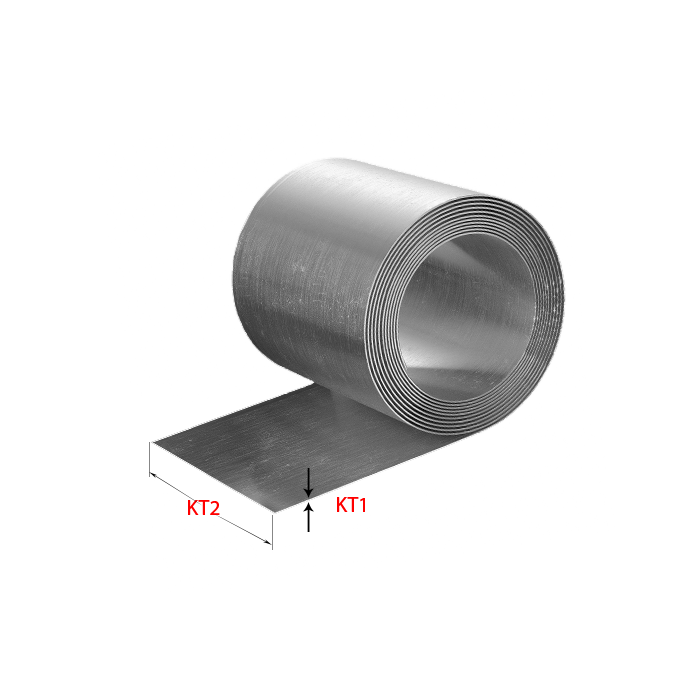

- Production Process: SUS 316L is produced through cold rolling to achieve the desired thickness and mechanical properties, then coiled for easy transportation and use.

- Fabrication: It can be easily processed through methods like cutting, welding, and forming, making it suitable for a wide range of applications.

(Source: Internet)

Key Characteristics of SUS 316L Stainless Steel Coil:

- Chemical Composition:

- Chromium (Cr): 16.0-18.0%, provides corrosion and oxidation resistance.

- Nickel (Ni): 10.0-14.0%, enhances corrosion resistance and ductility.

- Molybdenum (Mo): 2.0-3.0%, improves corrosion resistance in chloride and chemical environments.

- Carbon (C): Maximum 0.03%, reduces susceptibility to intergranular corrosion.

- Manganese (Mn): Maximum 2.0%, improves machinability.

- Silicon (Si): Maximum 1.0%, contributes to strength and corrosion resistance.

- Phosphorus (P) and Sulfur (S): Both are present in maximum amounts of 0.045% and 0.030% respectively, maintaining high steel purity.

- Physical Properties:

- High Corrosion Resistance: Due to the high molybdenum content, SUS 316L offers better corrosion resistance compared to SUS 304, particularly in seawater, chloride-containing water, and corrosive chemical environments.

- High Ductility and Strength: It has good tensile strength and ductility, making it easy to process and form.

- Oxidation Resistance: Good in high-temperature environments but not recommended for prolonged use above 800°C.

- Good Weldability: The low carbon content minimizes carbide precipitation during welding, reducing the risk of intergranular corrosion after welding.

- Applications:

- Chemical and Petrochemical Industry: Used in equipment and pipelines for transporting chemicals where high corrosion resistance is required.

- Marine Industry: Used in ship structures, machinery parts exposed to seawater, and marine environments.

- Medical and Food Processing Equipment: Used in manufacturing medical instruments, food processing equipment due to its corrosion resistance and ease of cleaning.

- Construction Industry: Used in exterior applications and architecture where long-term durability and corrosion resistance are required.

Manufacturing and Processing:

- Production Process: SUS 316L is produced through cold rolling to achieve the desired thickness and mechanical properties, then coiled for easy transportation and use.

- Fabrication: It can be easily processed through methods like cutting, welding, and forming, making it suitable for a wide range of applications.

(Source: Internet)