THÔNG TIN CƠ BẢN

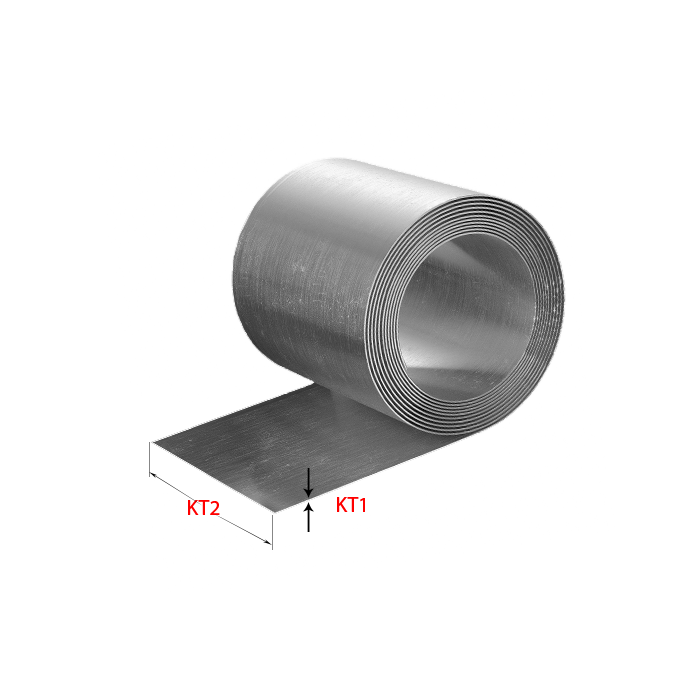

SUS 430 BA Stainless Steel Coil is a ferritic stainless steel containing about 16-18% chromium and little or no nickel. SUS 430 BA is known for its good corrosion resistance, high hardness, and bright surface finish due to the Bright Annealed (BA) treatment process. This steel is commonly used in applications requiring aesthetic surfaces and moderate corrosion resistance.

Key Characteristics of SUS 430 BA Stainless Steel Coil:

- Chemical Composition:

- Chromium (Cr): 16.0-18.0%, provides corrosion and oxidation resistance.

- Carbon (C): Maximum 0.12%, enhances the hardness of the steel.

- Manganese (Mn): Maximum 1.0%, improves machinability.

- Silicon (Si): Maximum 1.0%, contributes to strength and corrosion resistance.

- Phosphorus (P) and Sulfur (S): Both are present in maximum amounts of 0.040% and 0.030% respectively, maintaining high steel purity.

- Physical Properties:

- Corrosion Resistance: SUS 430 BA offers good corrosion resistance in various environments, particularly in weak acid and alkaline environments.

- Hardness and Strength: It has higher hardness and strength compared to austenitic stainless steels like SUS 304, though with lower ductility.

- Bright Surface Finish: The Bright Annealed (BA) process provides a smooth, glossy surface that enhances aesthetics and is easy to clean.

- Machinability: Easy to process and form, although it does not have as high pitting resistance as nickel-containing stainless steels.

- Applications:

- Household Appliances: Used in products like sinks, kitchen utensils, and appliances due to its bright surface and ease of cleaning.

- Construction Industry: Used in decorative panels, architectural facades, and interior applications.

- Automotive Industry: Used in the production of car parts, particularly exterior trim components.

- Industrial Equipment: Suitable for applications requiring moderate corrosion resistance and high durability.

Manufacturing and Processing:

- Production Process: SUS 430 BA is produced through cold rolling to achieve the desired thickness, followed by heat treatment using the Bright Annealed process to create a smooth and shiny surface.

- Fabrication: It can be easily processed through methods like cutting, welding, and bending, making it suitable for a variety of industrial and consumer applications.

(Source: Internet)

Key Characteristics of SUS 430 BA Stainless Steel Coil:

- Chemical Composition:

- Chromium (Cr): 16.0-18.0%, provides corrosion and oxidation resistance.

- Carbon (C): Maximum 0.12%, enhances the hardness of the steel.

- Manganese (Mn): Maximum 1.0%, improves machinability.

- Silicon (Si): Maximum 1.0%, contributes to strength and corrosion resistance.

- Phosphorus (P) and Sulfur (S): Both are present in maximum amounts of 0.040% and 0.030% respectively, maintaining high steel purity.

- Physical Properties:

- Corrosion Resistance: SUS 430 BA offers good corrosion resistance in various environments, particularly in weak acid and alkaline environments.

- Hardness and Strength: It has higher hardness and strength compared to austenitic stainless steels like SUS 304, though with lower ductility.

- Bright Surface Finish: The Bright Annealed (BA) process provides a smooth, glossy surface that enhances aesthetics and is easy to clean.

- Machinability: Easy to process and form, although it does not have as high pitting resistance as nickel-containing stainless steels.

- Applications:

- Household Appliances: Used in products like sinks, kitchen utensils, and appliances due to its bright surface and ease of cleaning.

- Construction Industry: Used in decorative panels, architectural facades, and interior applications.

- Automotive Industry: Used in the production of car parts, particularly exterior trim components.

- Industrial Equipment: Suitable for applications requiring moderate corrosion resistance and high durability.

Manufacturing and Processing:

- Production Process: SUS 430 BA is produced through cold rolling to achieve the desired thickness, followed by heat treatment using the Bright Annealed process to create a smooth and shiny surface.

- Fabrication: It can be easily processed through methods like cutting, welding, and bending, making it suitable for a variety of industrial and consumer applications.

(Source: Internet)