THÔNG TIN CƠ BẢN

SUS 316 COLD Stainless Steel is a type of SUS 316 stainless steel that has been processed through cold rolling. Compared to hot-rolled steel, cold-rolled steel has higher strength, better hardness, and greater precision.

Key Characteristics of SUS 316 COLD Stainless Steel:

- Chemical Composition:

- Chromium (Cr): 16-18%, providing corrosion resistance.

- Nickel (Ni): 10-14%, enhancing ductility and heat resistance.

- Molybdenum (Mo): 2-3%, improving corrosion resistance, especially in chloride environments.

- Carbon (C): Up to 0.08%, maintaining corrosion resistance.

- Manganese (Mn): 2%, supporting the steel structure.

- Silicon (Si): 1%, improving corrosion resistance and machinability.

- Physical Properties:

- Corrosion Resistance: Excellent in chloride environments, such as seawater and corrosive chemicals.

- Strength: Cold rolling increases the strength and hardness compared to hot-rolled steel.

- Ductility: Easily machinable, bendable, and cut without cracking or breaking.

- Applications:

- Chemical Industry: Used in equipment and components exposed to corrosive chemicals.

- Marine Industry: Suitable for applications in marine environments and highly corrosive conditions.

- Food Processing and Medical Industry: Used in food processing equipment and medical devices due to its corrosion resistance and ease of cleaning.

- Construction: Utilized in building components requiring high strength and good corrosion resistance.

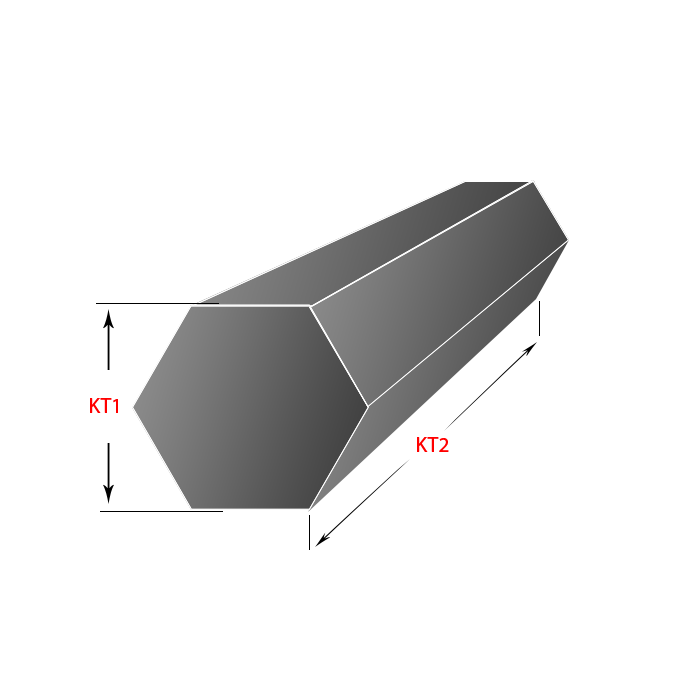

- Form and Size:

- SUS 316 COLD is typically available in sheets, bars, tubes, and wires, with sizes and shapes customized according to application needs.

Manufacturing and Processing:

- Production Process: SUS 316 COLD is produced through cold rolling, which enhances the steel’s strength, hardness, and precision.

- Machining: Can be machined using various mechanical methods such as cutting, drilling, and bending, while maintaining a good surface finish.

(Source: Internet)

Key Characteristics of SUS 316 COLD Stainless Steel:

- Chemical Composition:

- Chromium (Cr): 16-18%, providing corrosion resistance.

- Nickel (Ni): 10-14%, enhancing ductility and heat resistance.

- Molybdenum (Mo): 2-3%, improving corrosion resistance, especially in chloride environments.

- Carbon (C): Up to 0.08%, maintaining corrosion resistance.

- Manganese (Mn): 2%, supporting the steel structure.

- Silicon (Si): 1%, improving corrosion resistance and machinability.

- Physical Properties:

- Corrosion Resistance: Excellent in chloride environments, such as seawater and corrosive chemicals.

- Strength: Cold rolling increases the strength and hardness compared to hot-rolled steel.

- Ductility: Easily machinable, bendable, and cut without cracking or breaking.

- Applications:

- Chemical Industry: Used in equipment and components exposed to corrosive chemicals.

- Marine Industry: Suitable for applications in marine environments and highly corrosive conditions.

- Food Processing and Medical Industry: Used in food processing equipment and medical devices due to its corrosion resistance and ease of cleaning.

- Construction: Utilized in building components requiring high strength and good corrosion resistance.

- Form and Size:

- SUS 316 COLD is typically available in sheets, bars, tubes, and wires, with sizes and shapes customized according to application needs.

Manufacturing and Processing:

- Production Process: SUS 316 COLD is produced through cold rolling, which enhances the steel’s strength, hardness, and precision.

- Machining: Can be machined using various mechanical methods such as cutting, drilling, and bending, while maintaining a good surface finish.

(Source: Internet)