THÔNG TIN CƠ BẢN

SUS 440C Stainless Steel is a type of stainless steel in the martensitic group, known for its high hardness and excellent wear resistance. SUS 440C is commonly used in applications requiring higher mechanical strength and better wear resistance compared to other stainless steels.

Key Characteristics of SUS 440C Stainless Steel:

- Chemical Composition:

- Carbon (C): 0.95-1.20%

- Chromium (Cr): 16.00-18.00%

- Manganese (Mn): Max 1.00%

- Silicon (Si): Max 1.00%

- Phosphorus (P): Max 0.04%

- Sulfur (S): Max 0.03%

- Physical Properties:

- Wear Resistance: Excellent, due to high carbon content and martensitic structure. SUS 440C offers better wear resistance compared to other stainless steels like SUS 304 or SUS 316.

- Hardness: High, with hardness reaching up to HRC 58-60 after heat treatment, making it suitable for applications requiring high hardness and mechanical strength.

- Corrosion Resistance: Good in less aggressive environments. However, its corrosion resistance is not as good as SUS 304 or SUS 316, especially in highly corrosive environments.

- Applications:

- Cutlery and Tools Industry: Used in the production of knives, cutting blades, and other cutting tools due to its ability to maintain a sharp edge and high durability.

- Automotive Industry: Used in components requiring high hardness and wear resistance.

- Machinery Industry: Used in parts requiring high precision and wear resistance.

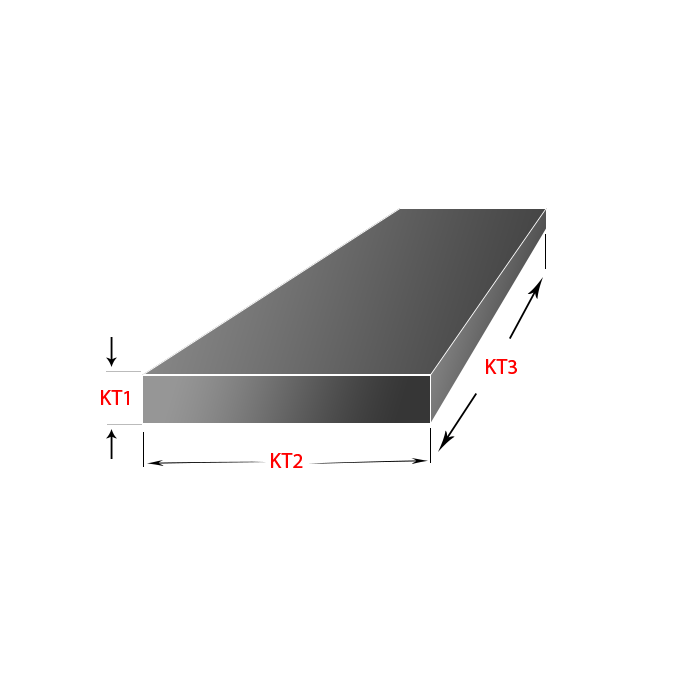

- Form and Size:

- SUS 440C is typically available in sheets, bars, tubes, or custom-fabricated products depending on specific application requirements.

Manufacturing and Processing:

- Production Process: SUS 440C steel is produced through metallurgy and heat treatment processes to achieve a martensitic structure and high hardness.

- Machining: Requires careful machining due to its high hardness. Welding and machining can be more challenging compared to other stainless steels.

(Source: Internet)

Key Characteristics of SUS 440C Stainless Steel:

- Chemical Composition:

- Carbon (C): 0.95-1.20%

- Chromium (Cr): 16.00-18.00%

- Manganese (Mn): Max 1.00%

- Silicon (Si): Max 1.00%

- Phosphorus (P): Max 0.04%

- Sulfur (S): Max 0.03%

- Physical Properties:

- Wear Resistance: Excellent, due to high carbon content and martensitic structure. SUS 440C offers better wear resistance compared to other stainless steels like SUS 304 or SUS 316.

- Hardness: High, with hardness reaching up to HRC 58-60 after heat treatment, making it suitable for applications requiring high hardness and mechanical strength.

- Corrosion Resistance: Good in less aggressive environments. However, its corrosion resistance is not as good as SUS 304 or SUS 316, especially in highly corrosive environments.

- Applications:

- Cutlery and Tools Industry: Used in the production of knives, cutting blades, and other cutting tools due to its ability to maintain a sharp edge and high durability.

- Automotive Industry: Used in components requiring high hardness and wear resistance.

- Machinery Industry: Used in parts requiring high precision and wear resistance.

- Form and Size:

- SUS 440C is typically available in sheets, bars, tubes, or custom-fabricated products depending on specific application requirements.

Manufacturing and Processing:

- Production Process: SUS 440C steel is produced through metallurgy and heat treatment processes to achieve a martensitic structure and high hardness.

- Machining: Requires careful machining due to its high hardness. Welding and machining can be more challenging compared to other stainless steels.

(Source: Internet)