THÔNG TIN CƠ BẢN

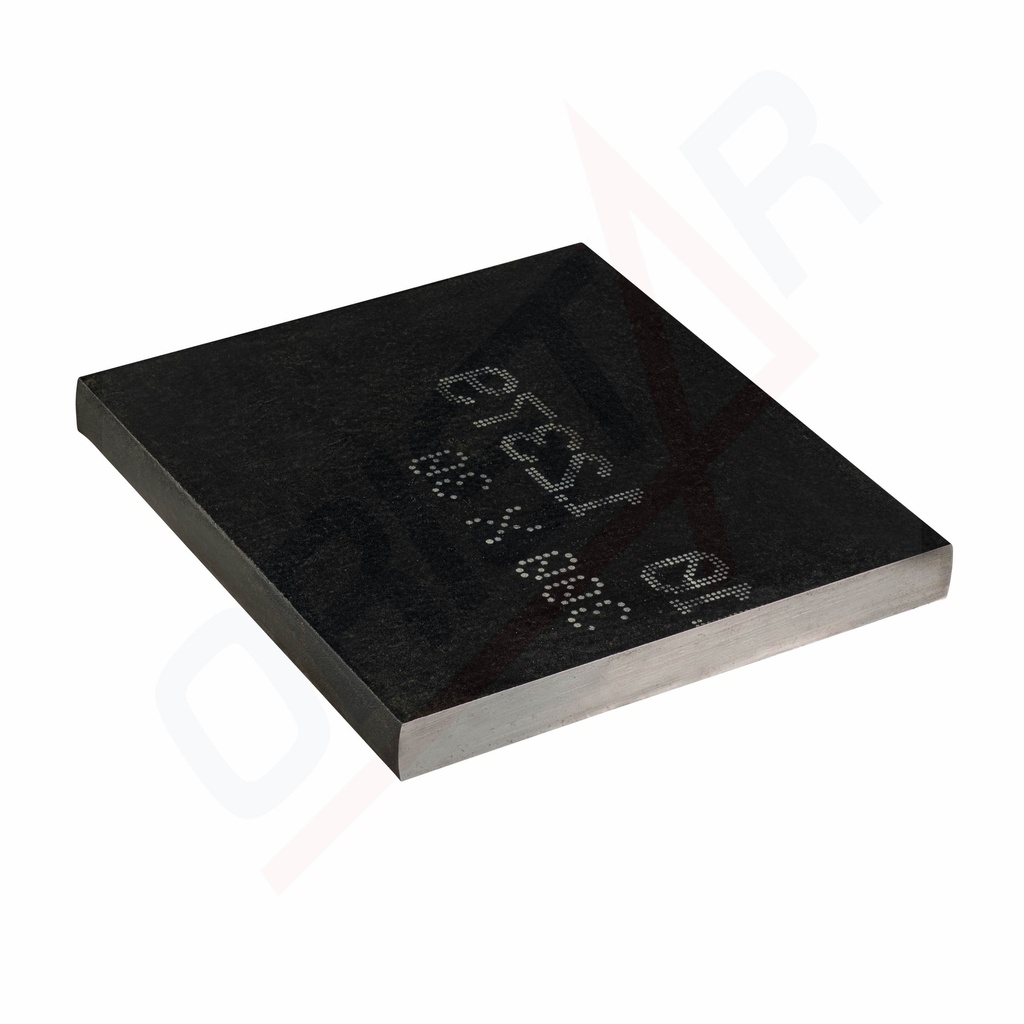

M238 HIGHHARD stainless steel is a high-quality tool steel developed with excellent wear resistance and high strength. Below are the key characteristics of this steel:

Chemical Composition:

It is a high chromium tool steel, typically containing other elements such as carbon, molybdenum, and vanadium, which enhance heat resistance and corrosion protection.

Mechanical Properties:

Hardness: M238 HIGHHARD has an exceptionally high hardness level in its delivered condition, suitable for applications requiring maximum hardness. Its hardness can reach around 50 HRC (Rockwell C).

Strength and Toughness: M238 HIGHHARD balances hardness and crack resistance, making it ideal for applications with high wear and heavy load conditions.

Machinability:

Despite its high hardness, this steel has good machinability, making it suitable for CNC machining or grinding.

Applications:

Widely used in the production of plastic injection molds, stamping dies, and other tools requiring high hardness and durability. It is also suitable for applications in industries such as automotive, electronics, and various other manufacturing sectors.

Heat Treatment:

M238 HIGHHARD can be heat-treated to achieve the desired hardness. It typically undergoes processes such as annealing, quenching, and tempering to optimize its mechanical properties and performance.

This steel is favored for its outstanding toughness and wear resistance, reducing maintenance and tool replacement during production processes.

(Source: Internet)

Chemical Composition:

It is a high chromium tool steel, typically containing other elements such as carbon, molybdenum, and vanadium, which enhance heat resistance and corrosion protection.

Mechanical Properties:

Hardness: M238 HIGHHARD has an exceptionally high hardness level in its delivered condition, suitable for applications requiring maximum hardness. Its hardness can reach around 50 HRC (Rockwell C).

Strength and Toughness: M238 HIGHHARD balances hardness and crack resistance, making it ideal for applications with high wear and heavy load conditions.

Machinability:

Despite its high hardness, this steel has good machinability, making it suitable for CNC machining or grinding.

Applications:

Widely used in the production of plastic injection molds, stamping dies, and other tools requiring high hardness and durability. It is also suitable for applications in industries such as automotive, electronics, and various other manufacturing sectors.

Heat Treatment:

M238 HIGHHARD can be heat-treated to achieve the desired hardness. It typically undergoes processes such as annealing, quenching, and tempering to optimize its mechanical properties and performance.

This steel is favored for its outstanding toughness and wear resistance, reducing maintenance and tool replacement during production processes.

(Source: Internet)