THÔNG TIN CƠ BẢN

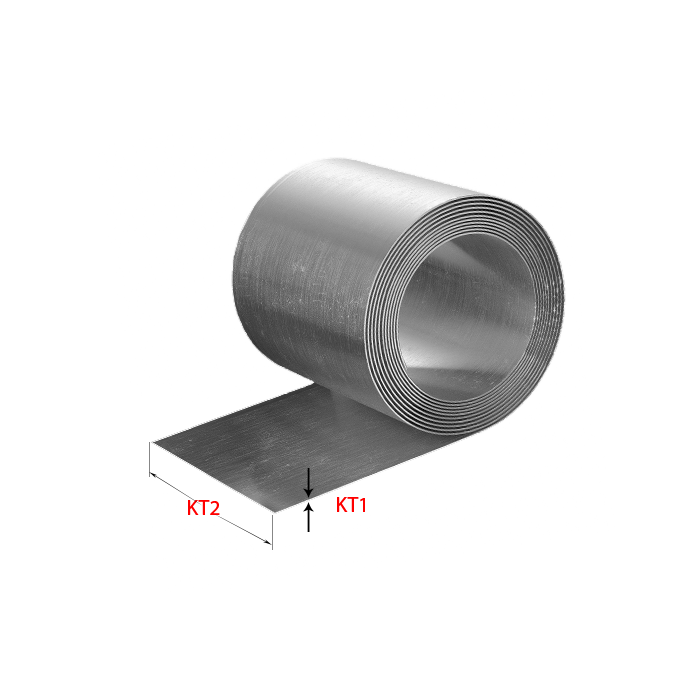

SUS 304 CSP Stainless Steel is a high-chromium, high-nickel austenitic stainless steel that has been cold-rolled to achieve higher hardness and strength compared to standard SUS 304. The "CSP" (Cold Rolled Steel Plate) designation refers to steel that has been cold-worked, enhancing its mechanical properties, particularly hardness, making it suitable for applications requiring high strength and elasticity.

Key Characteristics of SUS 304 CSP Stainless Steel:

- Chemical Composition:

- Chromium (Cr): 18.0-20.0%, provides corrosion and oxidation resistance.

- Nickel (Ni): 8.0-10.5%, enhances corrosion resistance and ductility.

- Carbon (C): Maximum 0.08%, reduces susceptibility to intergranular corrosion.

- Manganese (Mn): Maximum 2.0%, improves machinability.

- Silicon (Si): Maximum 1.0%, contributes to strength and corrosion resistance.

- Phosphorus (P) and Sulfur (S): Both are present in maximum amounts of 0.045% and 0.030% respectively, maintaining high steel purity.

- Physical Properties:

- High Hardness: Due to cold rolling, SUS 304 CSP has higher hardness, enhancing wear resistance and tensile strength.

- Corrosion Resistance: Like standard SUS 304, this grade offers good corrosion resistance in various environments, including humid and mildly corrosive settings.

- Ductility and Elasticity: Processed for high elasticity, making it suitable for applications like springs, washers, and mechanical parts requiring durability.

- Applications:

- Spring and Elastic Component Manufacturing: Due to its high hardness and elasticity, SUS 304 CSP is often used to produce springs, washers, and mechanical parts requiring good elasticity.

- Electronics and Home Appliances: Used in the production of electronic components, home appliances, where high ductility and strength are required.

- Automotive and Aerospace Industry: Utilized in parts requiring strength and good tensile properties.

Manufacturing and Processing:

- Production Process: SUS 304 CSP is produced through a cold rolling process, creating steel sheets with high strength and hardness.

- Fabrication: It can be easily fabricated through methods like cutting, welding, and bending, making it suitable for a wide range of applications.

(Source: Internet)

Key Characteristics of SUS 304 CSP Stainless Steel:

- Chemical Composition:

- Chromium (Cr): 18.0-20.0%, provides corrosion and oxidation resistance.

- Nickel (Ni): 8.0-10.5%, enhances corrosion resistance and ductility.

- Carbon (C): Maximum 0.08%, reduces susceptibility to intergranular corrosion.

- Manganese (Mn): Maximum 2.0%, improves machinability.

- Silicon (Si): Maximum 1.0%, contributes to strength and corrosion resistance.

- Phosphorus (P) and Sulfur (S): Both are present in maximum amounts of 0.045% and 0.030% respectively, maintaining high steel purity.

- Physical Properties:

- High Hardness: Due to cold rolling, SUS 304 CSP has higher hardness, enhancing wear resistance and tensile strength.

- Corrosion Resistance: Like standard SUS 304, this grade offers good corrosion resistance in various environments, including humid and mildly corrosive settings.

- Ductility and Elasticity: Processed for high elasticity, making it suitable for applications like springs, washers, and mechanical parts requiring durability.

- Applications:

- Spring and Elastic Component Manufacturing: Due to its high hardness and elasticity, SUS 304 CSP is often used to produce springs, washers, and mechanical parts requiring good elasticity.

- Electronics and Home Appliances: Used in the production of electronic components, home appliances, where high ductility and strength are required.

- Automotive and Aerospace Industry: Utilized in parts requiring strength and good tensile properties.

Manufacturing and Processing:

- Production Process: SUS 304 CSP is produced through a cold rolling process, creating steel sheets with high strength and hardness.

- Fabrication: It can be easily fabricated through methods like cutting, welding, and bending, making it suitable for a wide range of applications.

(Source: Internet)