THÔNG TIN CƠ BẢN

SUS 430 Stainless Steel is a type of stainless steel in the chromium stainless steel group, notable for its good corrosion resistance and ease of fabrication. It is commonly used in applications requiring good corrosion resistance and aesthetic appeal but does not demand the robust corrosion resistance of other stainless steels.

Key Characteristics of SUS 430 Stainless Steel:

- Chemical Composition:

- Carbon (C): Max 0.12%

- Chromium (Cr): 16.00-18.00%

- Nickel (Ni): Max 0.75%

- Manganese (Mn): Max 1.00%

- Silicon (Si): Max 1.00%

- Phosphorus (P): Max 0.04%

- Sulfur (S): Max 0.03%

- Physical Properties:

- Corrosion Resistance: Good in less aggressive environments, especially in high humidity or exposure to certain chemicals.

- Hardness: Sufficiently high to provide good mechanical strength, though not as high as other stainless steels like SUS 304.

- Machinability: Easy to machine and weld due to good ductility.

- Aesthetics: Has a shiny surface and is easy to maintain, making it suitable for applications requiring high aesthetic appeal.

- Applications:

- Household Industry: Used in household products like sinks, stoves, and kitchen appliances.

- Automotive Industry: Used in exhaust system parts and other components requiring corrosion resistance and aesthetics.

- Construction Industry: Utilized in architectural accessories, partitions, and decorative products.

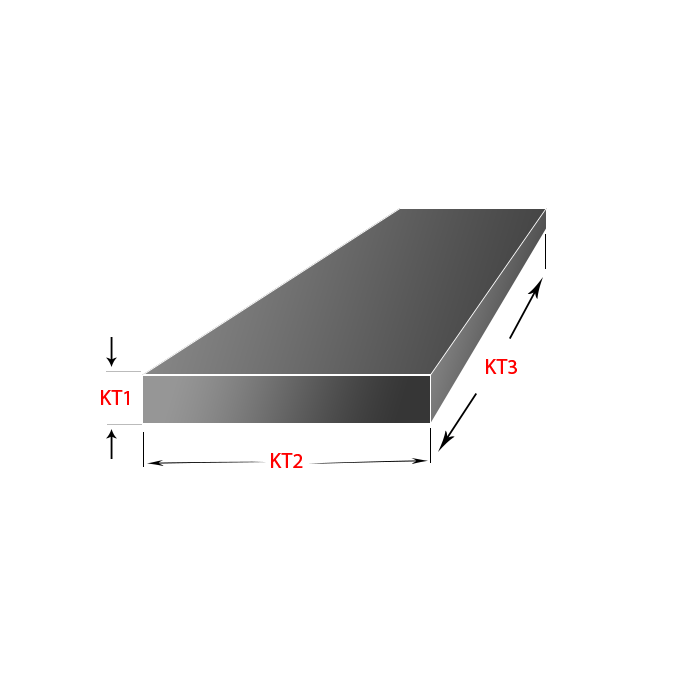

- Form and Size:

- SUS 430 is typically available in sheets, coils, bars, or custom-fabricated products depending on specific application requirements.

Manufacturing and Processing:

- Production Process: SUS 430 steel is produced through metallurgy processes to achieve the desired mechanical properties and corrosion resistance.

- Machining: Can be easily machined and welded due to its good ductility.

(Source: Internet)

Key Characteristics of SUS 430 Stainless Steel:

- Chemical Composition:

- Carbon (C): Max 0.12%

- Chromium (Cr): 16.00-18.00%

- Nickel (Ni): Max 0.75%

- Manganese (Mn): Max 1.00%

- Silicon (Si): Max 1.00%

- Phosphorus (P): Max 0.04%

- Sulfur (S): Max 0.03%

- Physical Properties:

- Corrosion Resistance: Good in less aggressive environments, especially in high humidity or exposure to certain chemicals.

- Hardness: Sufficiently high to provide good mechanical strength, though not as high as other stainless steels like SUS 304.

- Machinability: Easy to machine and weld due to good ductility.

- Aesthetics: Has a shiny surface and is easy to maintain, making it suitable for applications requiring high aesthetic appeal.

- Applications:

- Household Industry: Used in household products like sinks, stoves, and kitchen appliances.

- Automotive Industry: Used in exhaust system parts and other components requiring corrosion resistance and aesthetics.

- Construction Industry: Utilized in architectural accessories, partitions, and decorative products.

- Form and Size:

- SUS 430 is typically available in sheets, coils, bars, or custom-fabricated products depending on specific application requirements.

Manufacturing and Processing:

- Production Process: SUS 430 steel is produced through metallurgy processes to achieve the desired mechanical properties and corrosion resistance.

- Machining: Can be easily machined and welded due to its good ductility.

(Source: Internet)