THÔNG TIN CƠ BẢN

SPTE Non-Alloy Steel is a type of cold-rolled steel that is non-alloyed and is used primarily in applications that require stable mechanical properties and high machinability. SPTE is a variant of SPCC steel with additional technical requirements, commonly used in industries such as electronics manufacturing and mechanical processing.

Key Characteristics of SPTE Non-Alloy Steel:

- Chemical Composition:

- Carbon (C): Low, typically below 0.12%

- Manganese (Mn): Approximately 0.30% - 0.60%

- Silicon (Si): Approximately 0.15% - 0.35%

- Iron (Fe): The remainder

- Physical Properties:

- High Machinability: SPTE has excellent machinability and bending capabilities, suitable for applications requiring high precision and processing.

- Smooth and Uniform Surface: Cold-rolled to have a smooth and uniform surface, making it easy to paint or further process.

- Mechanical Stability: Ensures stability and strength in various industrial applications, especially in products requiring high precision.

- Applications:

- Electronics Industry: Used in electronic components, device housings, and products requiring smooth surfaces and high precision.

- Manufacturing: Used to produce mechanical parts and processing equipment where high machinability and durability are required.

- Automotive and Consumer Goods: Applied in the manufacture of automotive parts and consumer goods due to its stable mechanical properties and good machinability.

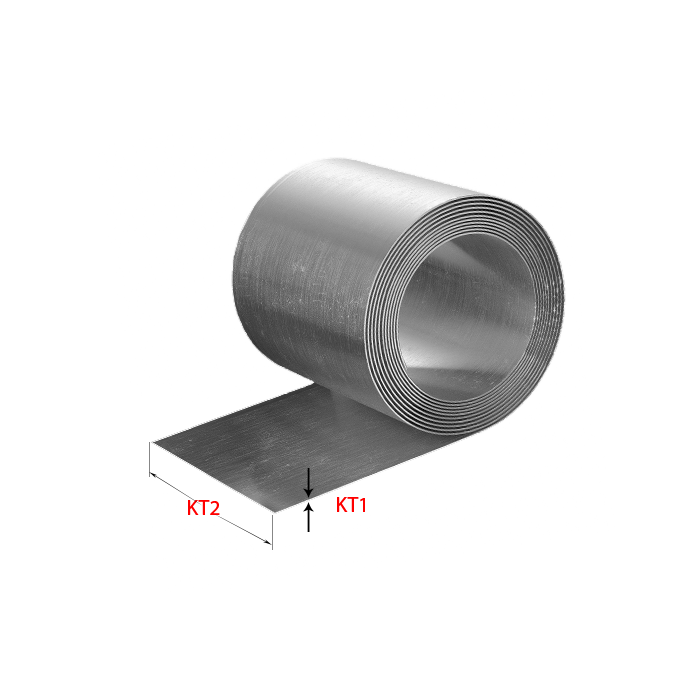

- Shape and Size:

- SPTE steel is typically supplied in forms such as plates, coils, or bars, depending on the specific application requirements.

Manufacturing and Processing:

- SPTE steel is produced through a cold rolling process similar to SPCC steel, with additional technical requirements to achieve the desired mechanical properties and surface finish. Cold rolling helps improve the surface and reduce the thickness of the steel while ensuring precision and high machinability.

(Source: Internet)

Key Characteristics of SPTE Non-Alloy Steel:

- Chemical Composition:

- Carbon (C): Low, typically below 0.12%

- Manganese (Mn): Approximately 0.30% - 0.60%

- Silicon (Si): Approximately 0.15% - 0.35%

- Iron (Fe): The remainder

- Physical Properties:

- High Machinability: SPTE has excellent machinability and bending capabilities, suitable for applications requiring high precision and processing.

- Smooth and Uniform Surface: Cold-rolled to have a smooth and uniform surface, making it easy to paint or further process.

- Mechanical Stability: Ensures stability and strength in various industrial applications, especially in products requiring high precision.

- Applications:

- Electronics Industry: Used in electronic components, device housings, and products requiring smooth surfaces and high precision.

- Manufacturing: Used to produce mechanical parts and processing equipment where high machinability and durability are required.

- Automotive and Consumer Goods: Applied in the manufacture of automotive parts and consumer goods due to its stable mechanical properties and good machinability.

- Shape and Size:

- SPTE steel is typically supplied in forms such as plates, coils, or bars, depending on the specific application requirements.

Manufacturing and Processing:

- SPTE steel is produced through a cold rolling process similar to SPCC steel, with additional technical requirements to achieve the desired mechanical properties and surface finish. Cold rolling helps improve the surface and reduce the thickness of the steel while ensuring precision and high machinability.

(Source: Internet)