THÔNG TIN CƠ BẢN

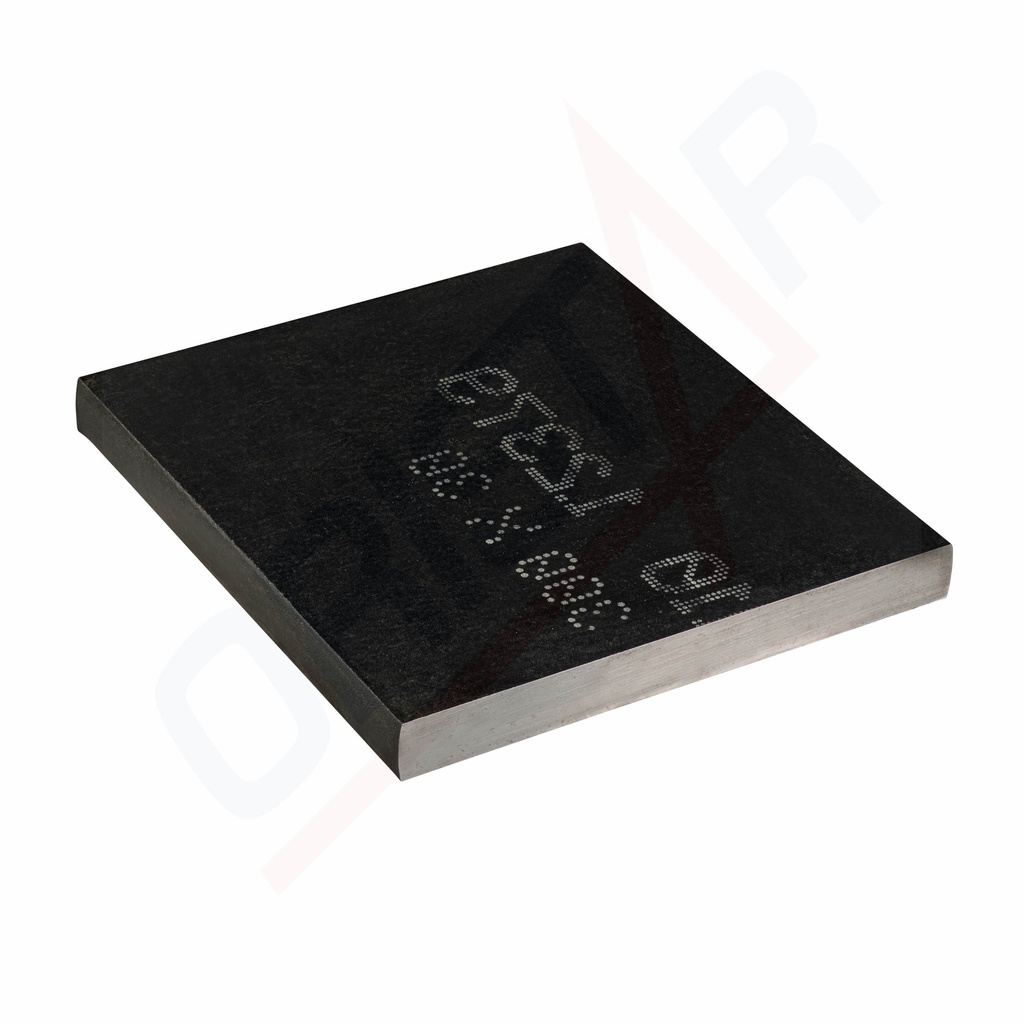

M310 ISOPLAST Stainless Steel is a special type of stainless steel designed to provide a balance between corrosion resistance, mechanical strength, and machinability. It is a popular choice for industrial applications requiring high precision and resistance to harsh environments.

Key Characteristics of M310 ISOPLAST Stainless Steel:

- Chemical Composition:

- Chromium (Cr): Around 24-26%, offers strong corrosion resistance.

- Nickel (Ni): Around 19-21%, supports the austenitic structure and enhances strength.

- Molybdenum (Mo): Around 3-4%, improves corrosion resistance in acidic environments.

- Nitrogen (N): Added to increase strength and durability.

- Carbon (C): Low, helps reduce carbide formation and enhance corrosion resistance.

- Physical Properties:

- High Corrosion Resistance: With Chromium and Molybdenum, this steel provides superior corrosion resistance in harsh environments, especially in acidic and chloride conditions.

- Strength and Hardness: The combination of alloys allows M310 ISOPLAST to have high strength and good wear resistance.

- Machinability: Despite excellent corrosion resistance, this steel retains good machinability for precise applications.

- Applications:

- Chemical Industry: Used in equipment and tools exposed to strong chemicals, such as chemical tanks and processing equipment.

- Oil and Gas Industry: Applied in components of oil and gas extraction equipment, requiring high corrosion resistance and durability.

- Aerospace Industry: Used in engine parts and aerospace structures needing strength and corrosion resistance.

- Machinery Manufacturing: Utilized in machine components requiring heat resistance and wear resistance.

Manufacturing and Processing:

- Production Process: M310 ISOPLAST is typically produced through melting and continuous casting, followed by heat treatment to achieve desired mechanical properties.

- Fabrication: This steel can be machined using methods such as turning, milling, and drilling, maintaining high precision and excellent surface finish.

(Source: Internet)

Key Characteristics of M310 ISOPLAST Stainless Steel:

- Chemical Composition:

- Chromium (Cr): Around 24-26%, offers strong corrosion resistance.

- Nickel (Ni): Around 19-21%, supports the austenitic structure and enhances strength.

- Molybdenum (Mo): Around 3-4%, improves corrosion resistance in acidic environments.

- Nitrogen (N): Added to increase strength and durability.

- Carbon (C): Low, helps reduce carbide formation and enhance corrosion resistance.

- Physical Properties:

- High Corrosion Resistance: With Chromium and Molybdenum, this steel provides superior corrosion resistance in harsh environments, especially in acidic and chloride conditions.

- Strength and Hardness: The combination of alloys allows M310 ISOPLAST to have high strength and good wear resistance.

- Machinability: Despite excellent corrosion resistance, this steel retains good machinability for precise applications.

- Applications:

- Chemical Industry: Used in equipment and tools exposed to strong chemicals, such as chemical tanks and processing equipment.

- Oil and Gas Industry: Applied in components of oil and gas extraction equipment, requiring high corrosion resistance and durability.

- Aerospace Industry: Used in engine parts and aerospace structures needing strength and corrosion resistance.

- Machinery Manufacturing: Utilized in machine components requiring heat resistance and wear resistance.

Manufacturing and Processing:

- Production Process: M310 ISOPLAST is typically produced through melting and continuous casting, followed by heat treatment to achieve desired mechanical properties.

- Fabrication: This steel can be machined using methods such as turning, milling, and drilling, maintaining high precision and excellent surface finish.

(Source: Internet)