THÔNG TIN CƠ BẢN

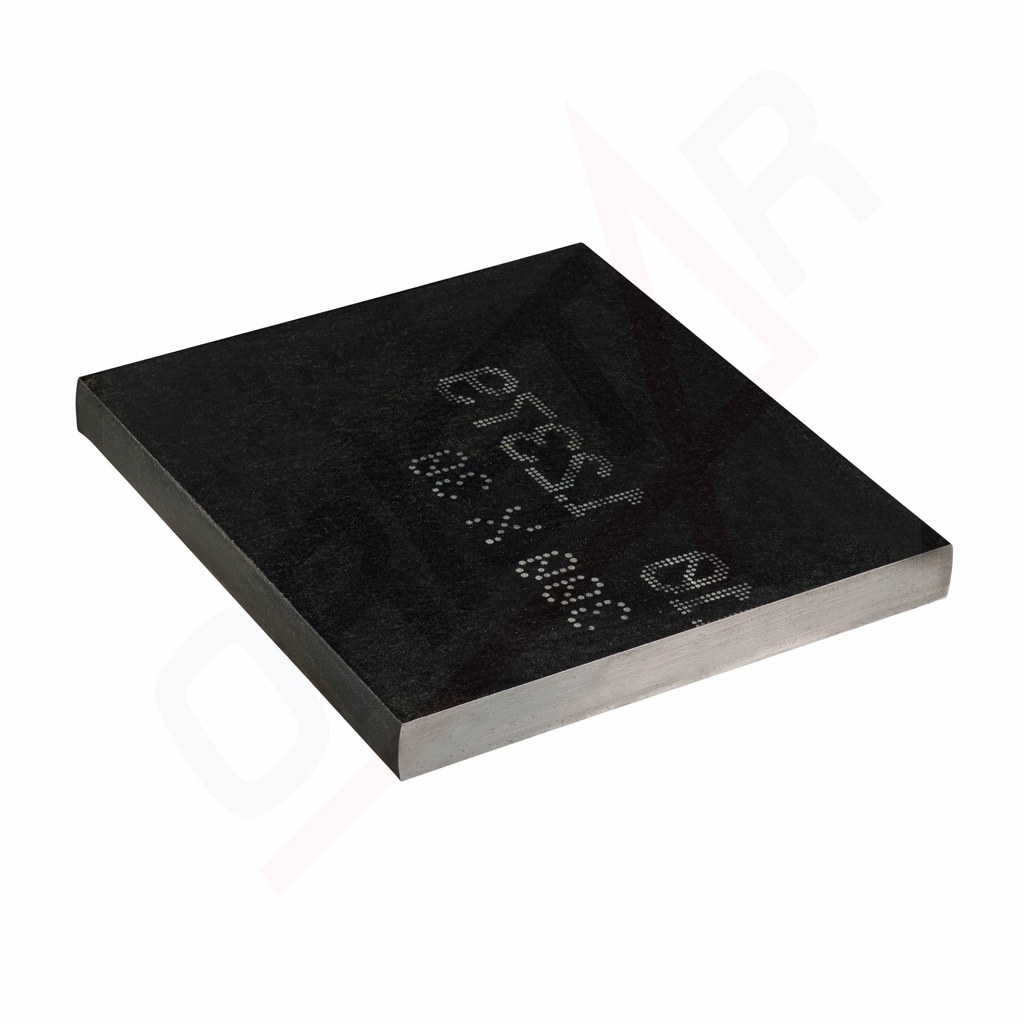

M315 EXTRA Stainless Steel is a high-grade stainless steel designed to enhance mechanical properties and corrosion resistance. It is developed based on the 316 stainless steel framework with additional alloys to improve performance in demanding applications.

Key Characteristics of M315 EXTRA Stainless Steel:

- Chemical Composition:

- Chromium (Cr): Around 16-18%, provides basic corrosion resistance.

- Nickel (Ni): Around 10-12%, supports the austenitic structure and enhances strength.

- Molybdenum (Mo): Around 3-4%, improves corrosion resistance in acidic and chloride environments.

- Nitrogen (N): Added to enhance hardness and strength.

- Carbon (C): Lower compared to other steels, reduces carbide formation and improves corrosion resistance.

- Physical Properties:

- Outstanding Corrosion Resistance: M315 EXTRA offers superior corrosion resistance compared to standard 316 stainless steel, especially in chloride and acidic environments.

- Strength and Hardness: This steel provides high strength and good wear resistance due to the additional alloying elements.

- Machinability: M315 EXTRA maintains good machinability, achieving high precision and excellent surface finish.

- Applications:

- Chemical Industry: Used in equipment and tools exposed to strong chemicals, including tanks and processing equipment.

- Oil and Gas Industry: Applied in components of oil and gas extraction equipment requiring high corrosion resistance and durability.

- Food Industry: Utilized in food processing equipment due to its corrosion resistance and ease of cleaning.

- Aerospace Industry: Employed in engine parts and aerospace structures where heat resistance and corrosion resistance are crucial.

Manufacturing and Processing:

- Production Process: M315 EXTRA is typically produced through specialized metallurgical processes and continuous casting, followed by heat treatment to achieve the best mechanical and corrosion-resistant properties.

- Fabrication: This steel can be machined using methods such as turning, milling, and drilling, maintaining high precision and excellent surface finish.

(Source: Internet)

Key Characteristics of M315 EXTRA Stainless Steel:

- Chemical Composition:

- Chromium (Cr): Around 16-18%, provides basic corrosion resistance.

- Nickel (Ni): Around 10-12%, supports the austenitic structure and enhances strength.

- Molybdenum (Mo): Around 3-4%, improves corrosion resistance in acidic and chloride environments.

- Nitrogen (N): Added to enhance hardness and strength.

- Carbon (C): Lower compared to other steels, reduces carbide formation and improves corrosion resistance.

- Physical Properties:

- Outstanding Corrosion Resistance: M315 EXTRA offers superior corrosion resistance compared to standard 316 stainless steel, especially in chloride and acidic environments.

- Strength and Hardness: This steel provides high strength and good wear resistance due to the additional alloying elements.

- Machinability: M315 EXTRA maintains good machinability, achieving high precision and excellent surface finish.

- Applications:

- Chemical Industry: Used in equipment and tools exposed to strong chemicals, including tanks and processing equipment.

- Oil and Gas Industry: Applied in components of oil and gas extraction equipment requiring high corrosion resistance and durability.

- Food Industry: Utilized in food processing equipment due to its corrosion resistance and ease of cleaning.

- Aerospace Industry: Employed in engine parts and aerospace structures where heat resistance and corrosion resistance are crucial.

Manufacturing and Processing:

- Production Process: M315 EXTRA is typically produced through specialized metallurgical processes and continuous casting, followed by heat treatment to achieve the best mechanical and corrosion-resistant properties.

- Fabrication: This steel can be machined using methods such as turning, milling, and drilling, maintaining high precision and excellent surface finish.

(Source: Internet)