THÔNG TIN CƠ BẢN

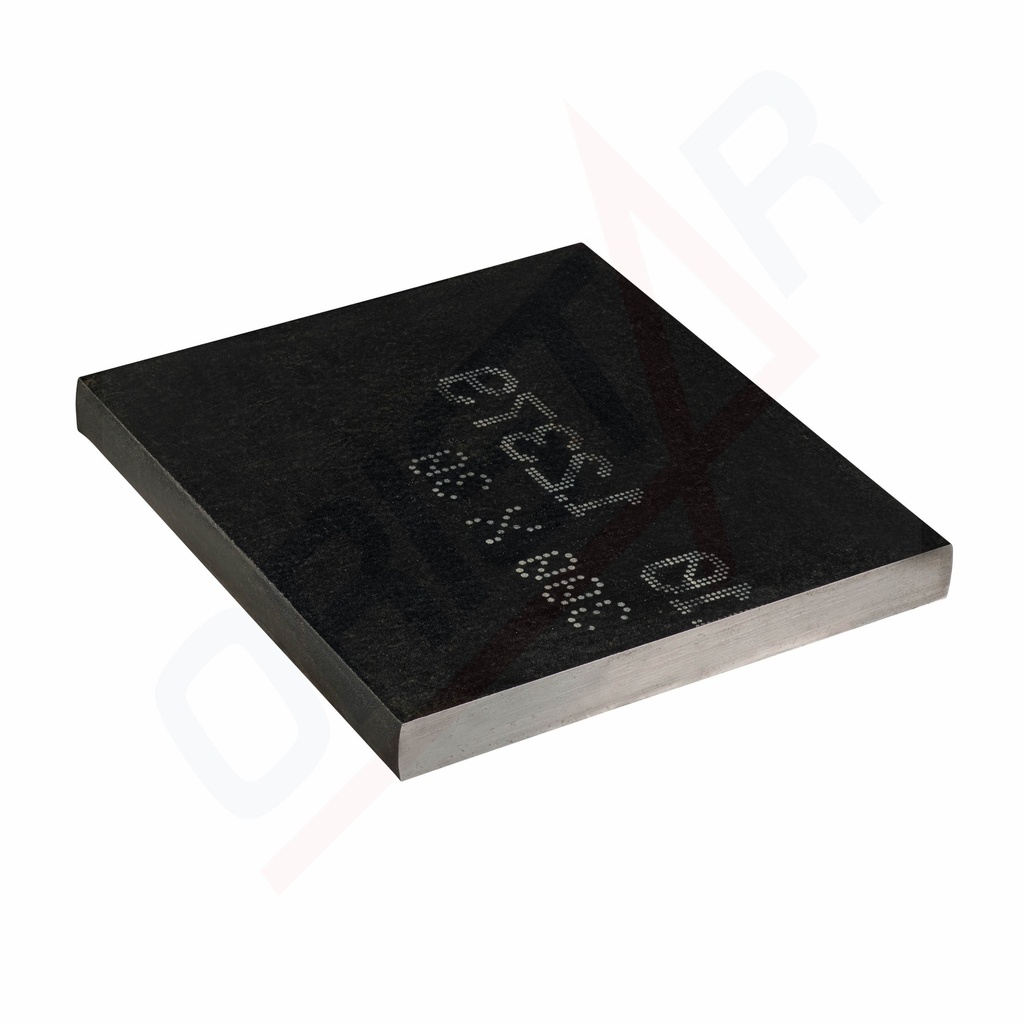

N690 Stainless Steel is a high-performance stainless steel with excellent mechanical properties and good corrosion resistance. It is widely used in applications requiring high strength and abrasion resistance.

Key Characteristics of N690 Stainless Steel:

- Chemical Composition:

- Carbon (C): 1.07%

- Chromium (Cr): 17.00-19.00%

- Molybdenum (Mo): 1.00-1.50%

- Vanadium (V): 0.10-0.30%

- Manganese (Mn): 0.30-0.50%

- Silicon (Si): 0.30-0.60%

- Phosphorus (P): Max 0.04%

- Sulfur (S): Max 0.03%

- Physical Properties:

- Corrosion Resistance: Good in various environments, including humid and chemical environments.

- Hardness: High, due to carbon content and vanadium alloy, suitable for applications requiring hardness and durability.

- Edge Retention: Excellent, particularly in cutting tools and knives.

- Ductility: Good, allowing for easy machining and welding.

- Applications:

- Cutlery Industry: Used in the production of knives, scissors, and other tools requiring high hardness and long-lasting edge retention.

- Tool Industry: Used in cutting and drilling tools that require high durability.

- Consumer Goods Industry: Utilized in consumer products requiring high corrosion resistance and strength.

- Form and Size:

- N690 steel is typically available in bars, plates, or custom-fabricated products depending on specific application requirements.

Manufacturing and Processing:

- Production Process: N690 steel is produced using metallurgy processes to achieve the desired mechanical properties and corrosion resistance.

- Machining: Can be easily machined and welded due to its good ductility.

(Source: Internet)

Key Characteristics of N690 Stainless Steel:

- Chemical Composition:

- Carbon (C): 1.07%

- Chromium (Cr): 17.00-19.00%

- Molybdenum (Mo): 1.00-1.50%

- Vanadium (V): 0.10-0.30%

- Manganese (Mn): 0.30-0.50%

- Silicon (Si): 0.30-0.60%

- Phosphorus (P): Max 0.04%

- Sulfur (S): Max 0.03%

- Physical Properties:

- Corrosion Resistance: Good in various environments, including humid and chemical environments.

- Hardness: High, due to carbon content and vanadium alloy, suitable for applications requiring hardness and durability.

- Edge Retention: Excellent, particularly in cutting tools and knives.

- Ductility: Good, allowing for easy machining and welding.

- Applications:

- Cutlery Industry: Used in the production of knives, scissors, and other tools requiring high hardness and long-lasting edge retention.

- Tool Industry: Used in cutting and drilling tools that require high durability.

- Consumer Goods Industry: Utilized in consumer products requiring high corrosion resistance and strength.

- Form and Size:

- N690 steel is typically available in bars, plates, or custom-fabricated products depending on specific application requirements.

Manufacturing and Processing:

- Production Process: N690 steel is produced using metallurgy processes to achieve the desired mechanical properties and corrosion resistance.

- Machining: Can be easily machined and welded due to its good ductility.

(Source: Internet)