THÔNG TIN CƠ BẢN

W302 ISODISC Alloy Steel is a high-quality alloy steel designed to provide superior hardness and wear resistance for specialized applications. This steel is commonly used in industries requiring exceptional performance and durability.

Key Characteristics of W302 ISODISC Alloy Steel:

- Chemical Composition:

- Carbon (C): 0.55-0.65%

- Chromium (Cr): 1.40-1.80%

- Molybdenum (Mo): 0.20-0.40%

- Vanadium (V): 0.10-0.20%

- Manganese (Mn): 0.50-0.80%

- Silicon (Si): 0.20-0.50%

- Phosphorus (P): Max 0.030%

- Sulfur (S): Max 0.030%

- Physical Properties:

- Hardness: W302 ISODISC can achieve high hardness, typically from HRC 58-62 after heat treatment.

- Wear Resistance: Excellent due to its unique alloy composition, enhancing wear resistance and product longevity.

- Impact Resistance: Improved due to the ISODISC manufacturing process, providing high durability and impact resistance.

- Applications:

- Mold Making Industry: Used in mold manufacturing for applications requiring high durability and wear resistance.

- Tool Manufacturing: Suitable for cutting tools and high-performance tools requiring hardness and heat resistance.

- Machine Tool Industry: Used in machine parts with requirements for load-bearing capacity and wear resistance.

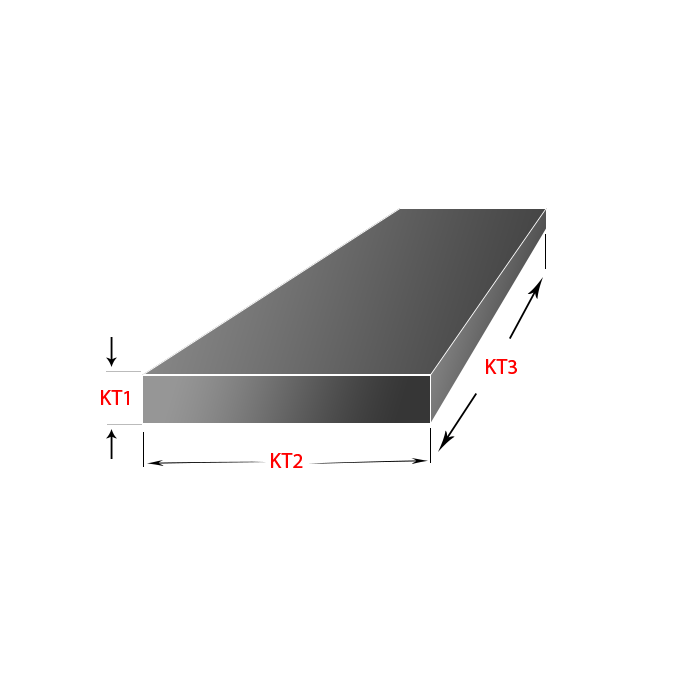

- Form and Size:

- W302 ISODISC is typically available in the form of plates, bars, or other custom-fabricated products based on application requirements.

Manufacturing and Processing:

- Production Process: W302 ISODISC is produced through the specialized ISODISC metallurgical process, enhancing the steel's quality and properties.

- Machining: Can be machined using methods such as cutting, welding, and heat treatment to achieve desired technical properties.

(Source: Internet)

Key Characteristics of W302 ISODISC Alloy Steel:

- Chemical Composition:

- Carbon (C): 0.55-0.65%

- Chromium (Cr): 1.40-1.80%

- Molybdenum (Mo): 0.20-0.40%

- Vanadium (V): 0.10-0.20%

- Manganese (Mn): 0.50-0.80%

- Silicon (Si): 0.20-0.50%

- Phosphorus (P): Max 0.030%

- Sulfur (S): Max 0.030%

- Physical Properties:

- Hardness: W302 ISODISC can achieve high hardness, typically from HRC 58-62 after heat treatment.

- Wear Resistance: Excellent due to its unique alloy composition, enhancing wear resistance and product longevity.

- Impact Resistance: Improved due to the ISODISC manufacturing process, providing high durability and impact resistance.

- Applications:

- Mold Making Industry: Used in mold manufacturing for applications requiring high durability and wear resistance.

- Tool Manufacturing: Suitable for cutting tools and high-performance tools requiring hardness and heat resistance.

- Machine Tool Industry: Used in machine parts with requirements for load-bearing capacity and wear resistance.

- Form and Size:

- W302 ISODISC is typically available in the form of plates, bars, or other custom-fabricated products based on application requirements.

Manufacturing and Processing:

- Production Process: W302 ISODISC is produced through the specialized ISODISC metallurgical process, enhancing the steel's quality and properties.

- Machining: Can be machined using methods such as cutting, welding, and heat treatment to achieve desired technical properties.

(Source: Internet)