THÔNG TIN CƠ BẢN

S45CR Non-Alloy Steel is a medium-carbon steel that is heat-treated to enhance its mechanical properties and strength. S45CR is commonly used in applications requiring higher strength and hardness compared to low-carbon steels.

Key Characteristics of S45CR Non-Alloy Steel:

- Chemical Composition:

- Carbon (C): Approximately 0.42-0.50%, providing hardness and strength to the steel.

- Manganese (Mn): Approximately 0.60-0.90%, enhances ductility and impact resistance.

- Silicon (Si): Approximately 0.15-0.35%, helps in hardening the steel and improving corrosion resistance.

- Chrome (Cr): Approximately 0.90-1.20%, provides wear resistance and improves strength.

- Physical Properties:

- Tensile Strength: Approximately 600-800 MPa, allowing the steel to withstand significant loads in demanding applications.

- Hardness: Can achieve high hardness after quenching and tempering, typically in the range of 28-32 HRC (Rockwell C).

- Machinability: Good, can be machined using conventional methods like turning, milling, and grinding after heat treatment.

- Applications:

- Machinery Manufacturing: Used for producing machine components with high strength requirements such as shafts, gears, and load-bearing parts.

- Automotive Industry: Applied in automotive parts like camshafts, crankshafts, and components requiring high strength.

- Heavy Industry: Used in machinery and industrial equipment requiring high strength and hardness.

- Construction: Utilized in construction elements with high load-bearing requirements.

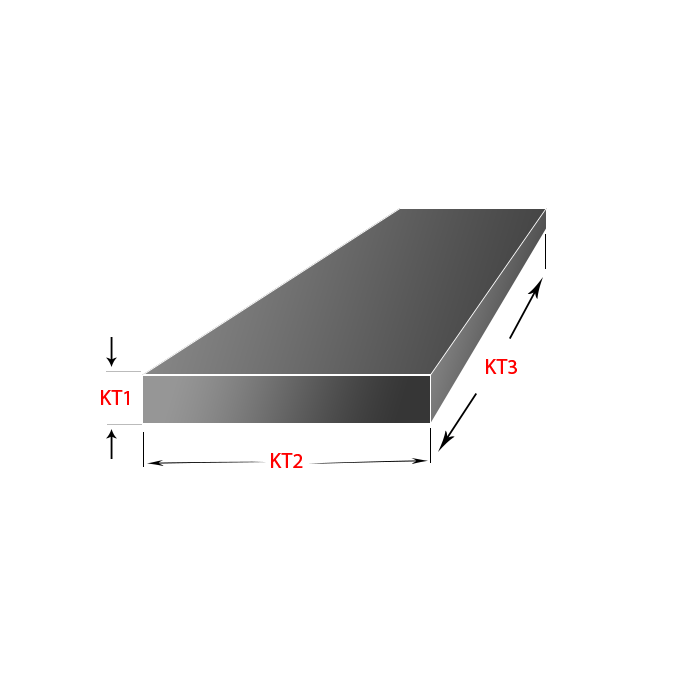

- Shape and Size:

- S45CR steel is commonly supplied in bars, tubes, plates, or customized products according to customer specifications.

Manufacturing and Processing:

- S45CR steel is typically produced through basic steelmaking processes and heat treatment to achieve the desired mechanical properties. Processing usually includes steps such as heating, quenching, and tempering to enhance hardness and strength.

(Source: Internet)

Key Characteristics of S45CR Non-Alloy Steel:

- Chemical Composition:

- Carbon (C): Approximately 0.42-0.50%, providing hardness and strength to the steel.

- Manganese (Mn): Approximately 0.60-0.90%, enhances ductility and impact resistance.

- Silicon (Si): Approximately 0.15-0.35%, helps in hardening the steel and improving corrosion resistance.

- Chrome (Cr): Approximately 0.90-1.20%, provides wear resistance and improves strength.

- Physical Properties:

- Tensile Strength: Approximately 600-800 MPa, allowing the steel to withstand significant loads in demanding applications.

- Hardness: Can achieve high hardness after quenching and tempering, typically in the range of 28-32 HRC (Rockwell C).

- Machinability: Good, can be machined using conventional methods like turning, milling, and grinding after heat treatment.

- Applications:

- Machinery Manufacturing: Used for producing machine components with high strength requirements such as shafts, gears, and load-bearing parts.

- Automotive Industry: Applied in automotive parts like camshafts, crankshafts, and components requiring high strength.

- Heavy Industry: Used in machinery and industrial equipment requiring high strength and hardness.

- Construction: Utilized in construction elements with high load-bearing requirements.

- Shape and Size:

- S45CR steel is commonly supplied in bars, tubes, plates, or customized products according to customer specifications.

Manufacturing and Processing:

- S45CR steel is typically produced through basic steelmaking processes and heat treatment to achieve the desired mechanical properties. Processing usually includes steps such as heating, quenching, and tempering to enhance hardness and strength.

(Source: Internet)