THÔNG TIN CƠ BẢN

SWB Non-Alloy Steel is a type of steel primarily used in the production of products requiring high elasticity and strength, similar to other spring steels. SWB is designed to withstand tensile stress and has good elasticity, making it suitable for various industrial applications, especially in products requiring elasticity like springs.

Key Characteristics of SWB Non-Alloy Steel:

- Chemical Composition:

- Carbon (C): Approximately 0.60% - 0.75%

- Manganese (Mn): Approximately 0.30% - 0.90%

- Silicon (Si): Approximately 0.10% - 0.35%

- Iron (Fe): The remainder

- Physical Properties:

- High Tensile Strength: SWB steel has high tensile strength, enhancing its ability to withstand force and provide durability in applications requiring these features.

- Good Hardness and Elasticity: SWB possesses high hardness and elasticity, making it suitable for the production of springs and machine components requiring elasticity.

- Wear Resistance: This steel type offers good wear resistance, ensuring product longevity under harsh working conditions.

- Applications:

- Spring Manufacturing: Widely used in the production of various mechanical springs, compression springs, tension springs, and other types of springs.

- Automotive Industry: Used in automotive parts requiring durability and elasticity, such as suspension systems.

- Precision Mechanics: Applied in machine components requiring high precision and elasticity.

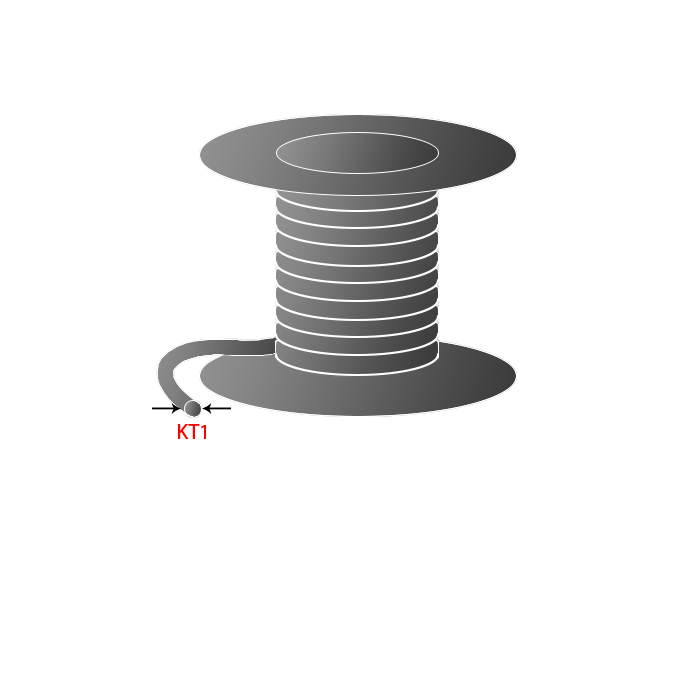

- Shape and Size:

- SWB steel is typically supplied in wire form, with different diameters depending on specific application requirements.

Manufacturing and Processing:

- SWB steel is produced through a wire drawing process from high-carbon steel, followed by heat treatment to achieve the desired mechanical properties. The manufacturing process requires strict quality control to ensure the product meets technical standards.

(Source: Internet)

Key Characteristics of SWB Non-Alloy Steel:

- Chemical Composition:

- Carbon (C): Approximately 0.60% - 0.75%

- Manganese (Mn): Approximately 0.30% - 0.90%

- Silicon (Si): Approximately 0.10% - 0.35%

- Iron (Fe): The remainder

- Physical Properties:

- High Tensile Strength: SWB steel has high tensile strength, enhancing its ability to withstand force and provide durability in applications requiring these features.

- Good Hardness and Elasticity: SWB possesses high hardness and elasticity, making it suitable for the production of springs and machine components requiring elasticity.

- Wear Resistance: This steel type offers good wear resistance, ensuring product longevity under harsh working conditions.

- Applications:

- Spring Manufacturing: Widely used in the production of various mechanical springs, compression springs, tension springs, and other types of springs.

- Automotive Industry: Used in automotive parts requiring durability and elasticity, such as suspension systems.

- Precision Mechanics: Applied in machine components requiring high precision and elasticity.

- Shape and Size:

- SWB steel is typically supplied in wire form, with different diameters depending on specific application requirements.

Manufacturing and Processing:

- SWB steel is produced through a wire drawing process from high-carbon steel, followed by heat treatment to achieve the desired mechanical properties. The manufacturing process requires strict quality control to ensure the product meets technical standards.

(Source: Internet)